Continuity

In this tutorial, you learn how to create continuity between surfaces and between curves.

The three main types of continuity used in Alias are shown in the following illustrations of three curves.

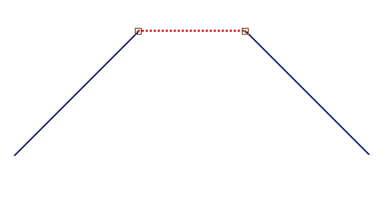

- Positional Continuity

-

The dashed curve touches the two solid curves, but there is an angle between them and so there is a sharp break between the curves.

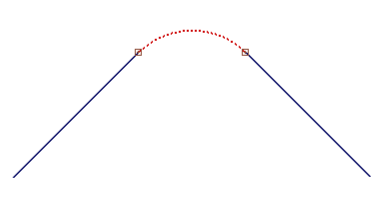

- Tangent Continuity

-

The dashed curve has no angle difference where it meets the solid curves. The Round surface tool and the Curve Fillet tool create this type of continuity.

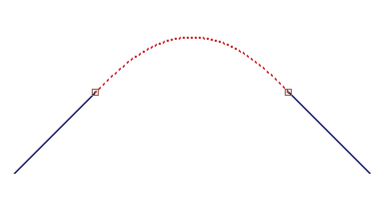

- Curvature Continuity

-

The dashed curve blends in even more smoothly to the solid curves.

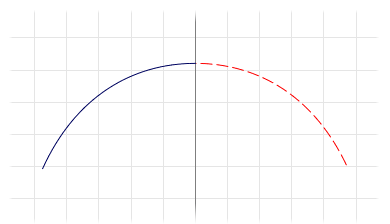

There is one other use of continuity used in this tutorial: Implied Tangent.

- Implied Tangent

-

A curve or surface is created on the center line, and is mirrored. The Implied Tangent tools make sure that the two surfaces (original and mirrored) are tangent to each other.

Understanding these concepts and using the tools that control them enables you to create smooth, organic designs in Alias.

Construction Tolerances

Construction Tolerances are also important when matching surfaces.

Construction tolerances specify the accuracy of the Position, Tangent, and Curvature continuity when surfaces are built. The accuracy is important if the model is used for manufacture or is transferred to another CAD system.

For more detailed information, see Continuity and Preferences > Construction Options![]() .

.