The direction the part is ejected from the mold is called the pull direction. This direction is used to determine the draft angle, undercuts, and mold cost.

If no pull direction is defined, a three tiered approach is adopted.

- The principle axes are examined. The axis with the least amount of undercuts will be used. If there are no undercuts on any axis, or if all axes have significant undercuts, the second method is adopted.

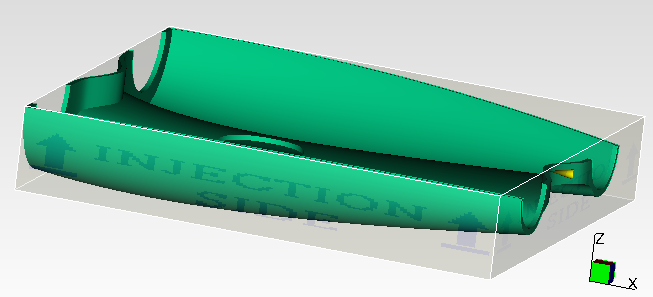

- Bounding box for the part is examined. The bounding box is the smallest box in the XYZ planes that contain the model.

The pull direction is perpendicular to the side of the bounding box with the largest area. If all the bounding box sides have the same area, the third method is adopted.

- The default Z axis is used.