A simulation depends on accurate information. It is important that you model accurately and specify the actual physical conditions (constraints, loads, materials, contact conditions). The accuracy of these conditions directly influences the quality of your results.

The stress analysis that Autodesk Inventor Simulation provides is appropriate only for linear material properties. These properties are where the stress is directly proportional to the strain in the material (meaning no permanent yielding of the material). Linear behavior results when the slope of the material stress-strain curve in the elastic region (measured as the Modulus of Elasticity) is constant.

The total deformation is assumed to be small in comparison to the part thickness. For example, if studying the deflection of a beam, the calculated displacement must be less than the minimum cross-section of the beam.

The results are temperature-independent. The temperature is assumed not to affect the material properties.

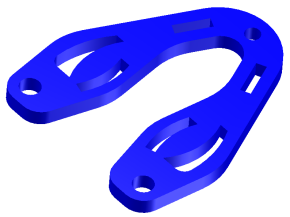

The following is a block (model) with well-defined mechanical and modal behaviors.

In this example of a simple part, the structural behavior would be difficult to predict solving equations by hand.

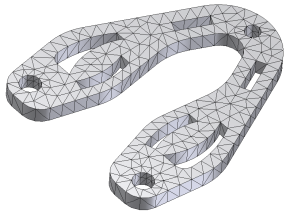

Here, the same part is broken into small elements, each with well-defined behaviors capable of being summed (solved) and easily interpreted (post-processed).