You place and constrain connectors in an assembly just as you place and constrain standard Autodesk Inventor parts. Once placed, with a harness assembly added, you set a specific reference designator for each occurrence of that part in the context of each harness assembly.

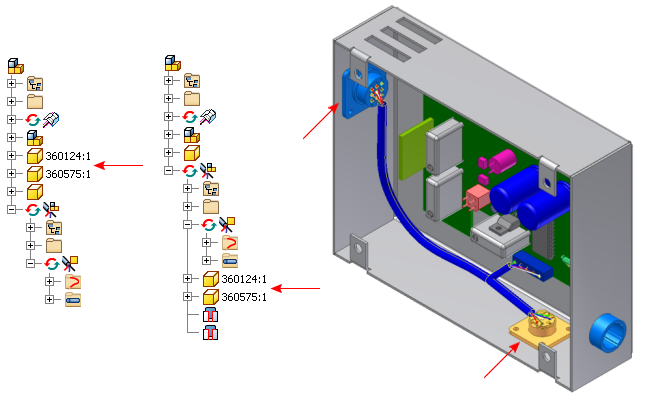

Connectors can be placed anywhere within the assembly structure. They can be placed outside of the harness assembly or demoted into the harness assembly, depending on how you prefer to document the harness assembly. Connectors that already reside within subassemblies can remain there.

If the connector is physically part of the harness, like a mating connector, consider adding it directly to the appropriate harness assembly. An object such as a terminal block that is not part of the harness, probably does not belong in the harness assembly. The process for adding wires is the same for both cases.

If reusing a top-level assembly that contains a harness assembly, we recommend that you demote the connectors into the harness assembly. From within Cable and Harness, use Save Copy As to copy the top-level assembly and its contents (the harness assembly, other subassemblies, and so on). Then you can reuse it in another assembly.

When placing and constraining mating connectors for a harness assembly, remember the following information:

- When the connectors reside in the harness assembly, they can be constrained to objects in the top-level assembly only while editing the top-level assembly. The connectors cannot be constrained while in-place editing the harness assembly.

- In your initial design, it is good practice to place the connectors in the top-level assembly without constraints. Then you are not unsure whether to place mating connectors as children of the top-level assembly or in the harness assembly. Using this method, you can demote the connectors into the harness assembly before the harness is created without losing constraints. Any RefDes information added to a connector at the time they are demoted is lost and must be edited to reassign the RefDes in the harness. Any wires or cables attached to connectors at the time they are demoted dangle. Edit them to reassign the wires to the connector pins. In summary, it is best to set the assembly structure before you apply harness properties and create wires.

- Constraints placed in the harness assembly provide more flexibility for individual components within the harness to adapt to assembly changes. They do not adapt to changes as a rigid body. For example, with a top-level assembly, if you constrain to a subassembly, all the parts in the subassembly move as one rigid body. With a harness assembly, you can constrain all connectors in the subassembly to different locations and they adapt independently of one another. They do not move as a rigid body.