- On the ribbon, click

3D Model tab

Modify panel

Modify panel

Shell

Shell

.

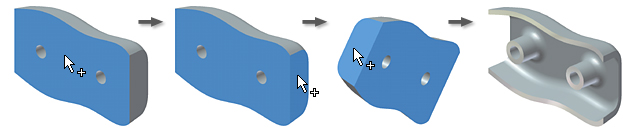

. - Click Remove Faces, and select the faces to remove in the graphics window. If multiple tangent faces are highlighted with a single selection, and this selection is not ideal, clear the check box for the Automatic Face Chain option before selecting.

- Click Solids if available in a multi-body part file to choose the participating solids.

- Click a direction button to specify the direction of the shell offset from the surface of the selected face (inside, outside, or both).

- Enter the default face thickness.

- To change how approximate shelling solutions are computed, click the More tab.

- To prevent approximate shelling, clear the Allow approximation check box.

- To determine where the deviation is distributed, click the arrow to select from the list.

- To specify the accuracy of the computation, select the appropriate option. If Specify tolerance is selected, enter a tolerance in the box.

- To change the thickness of a specific shell face, click More.

- Click in the row, then select one or more faces.

- In the Thickness box, enter the face thickness.

Continue to change face thickness, as needed.

- Click OK.

- If an approximation is used, click OK in the message box to accept the results or Edit to return to the Shell dialog box More tab.

Show Me how to create a shell feature

Show Me how to create a shell feature Show Me how to create a shell with unique face thicknesses

Show Me how to create a shell with unique face thicknesses

Tip: To reset a shell face to its original thickness, click in the Thickness box for that face, then press Delete.