|

The Corner Seam Rip option is useful in a limited number of cases with part models converted to sheet metal models. |

Note: Be sure to have a uniform thickness model following your conversion and that this thickness equals the material thickness defined in your active Sheet Metal Style.

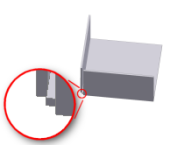

- Use the Corner Seam Rip option to open an edge between faces that you later use to flatten the converted part model. Note: The resulting open corner typically leaves material that must be removed.

- Create a sketch and manually remove the material using a Cut.

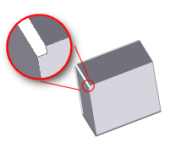

- Following the cut operation to clean out the remaining corner material, use the Bend command on the inside edges of what would have been modeled as flanges.

Note: Bends are typically best placed on inside edges.

Note: Bends are typically best placed on inside edges. - Once you rip and clean up all corners, and manually apply bends, you can flatten your model.