Transferred torque

where:

|

P |

power [kW] |

|

|

n |

speed [rpm] |

Calculation of Minimum Shaft Diameter

1. shaft inside diameter d h > 0

a)

b) if d min ≤d h -> d min = 1.1 d h [mm]

c) if d min ≤ 1.5 d h -> d min = 1.5 d h [mm]

2. shaft inside diameter d h = 0

where:

|

d min |

minimal shaft diameter [mm] |

|

|

d h |

shaft inside diameter [mm] |

|

|

T |

torque [Nm] |

|

|

K a |

application factor |

|

|

K f |

fatigue-life factor |

|

|

S v |

desired safety |

|

|

τ A |

Allowable Shear Stress |

General calculation

|

|

the range of force activity on the shaft |

|

h k = h - h s - 2 s [mm] |

the range of force activity on the hub |

|

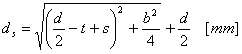

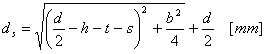

shaft diameter of the range of the force activity |

|

hub diameter of the range of the force activity |

|

|

force on shaft |

|

|

force on hub |

|

where: |

|

T |

torque [Nm] |

|

|

F s |

force on shaft [N] |

|

|

F h |

force on hub [N] |

|

|

K a |

application factor |

|

|

K f |

wear-life factor |

|

|

K w |

application factor |

|

|

K m |

load distribution factor |

|

|

S v |

desired safety |

|

|

d |

shaft diameter [mm] |

|

|

d s |

shaft diameter where force F s actuates [mm] |

|

|

d h |

shaft diameter where force F d actuates [mm] |

|

|

N |

number of grooves [-] |

|

|

h |

height of groove |

|

|

h s |

height of force point of action on shaft [mm] |

|

|

h h |

height of force point of action on hub [mm] |

|

|

b |

width of groove |

|

|

t |

groove depth in shaft [mm] |

|

|

s |

chamfer |

|

|

p Dmins |

minimal allowable pressure (groove, shaft) [MPa] |

|

|

p Dminh |

minimal allowable pressure (groove, hub) [MPa] |

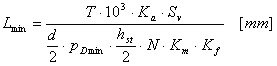

Minimum key length to transfer the torque

|

1. Fixed connection: |

a) |

|

b) |

|

|

L min = min(L mins , L minh ) |

|

|

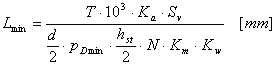

2. Flexible connection: |

a) |

|

b) |

|

|

L min = min(L mins , L minh ) |

|

|

where: |

|

F s |

force on shaft [N] |

|

|

F h |

force on hub [N] |

|

|

K a |

application factor |

|

|

K f |

wear-life factor |

|

|

K w |

application factor |

|

|

K m |

load distribution factor |

|

|

S v |

desired safety |

|

|

d |

shaft diameter [mm] |

|

|

N |

number of grooves [-] |

|

|

h s |

height of force point of action on shaft [mm] |

|

|

h h |

height of force point of action on hub [mm] |

|

|

p Dmins |

minimal allowable pressure (groove, shaft) [MPa] |

|

|

p Dminh |

minimal allowable pressure (groove, hub) [MPa] |

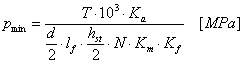

Minimal Allowable pressure

|

1. Fixed connection: |

a) |

|

b) |

|

|

2. Flexible connection: |

a) |

|

b) |

|

|

where: |

|

F s |

force on shaft [N] |

|

|

F h |

force on hub [N] |

|

|

K a |

application factor |

|

|

K f |

wear-life factor |

|

|

K w |

application factor |

|

|

K m |

load distribution factor |

|

|

S v |

desired safety |

|

|

d |

inside diameter of groove section [mm] |

|

|

N |

number of grooves [-] |

|

|

h s |

height of force point of action on shaft [mm] |

|

|

h h |

height of force point of action on hub [mm] |

|

|

l f |

active key length [mm] |

Strength Check

p mins ≤ p Ds

p minh ≤ p Dh

where:

|

p mins |

minimal calculated shear pressure in shaft [MPa] |

|

|

p minh |

minimal calculated shear pressure in hub [MPa] |

|

|

p Ds |

allowable pressure in shaft [Mpa] |

|

|

p Dh |

allowable pressure in hub [Mpa] |

Simplified calculation

Minimum key length to transfer the torque

|

1. Fixed connection: |

|

|

2. Flexible connection: |

|

|

where: |

|

T |

torque [Nm] |

|

|

K a |

application factor |

|

|

K f |

wear-life factor |

|

|

K w |

application factor |

|

|

K m |

load distribution factor |

|

|

S v |

desired safety |

|

|

d |

shaft diameter [mm] |

|

|

N |

number of grooves [-] |

|

|

h |

height of groove |

|

|

s |

chamfer |

|

|

h st |

connection height h st = h - 2 s [mm] |

|

|

p Dmin |

allowable pressure on supporting surface of shaft, groove, or hub [MPa] |

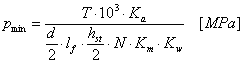

Allowable pressure

|

1. Fixed connection: |

|

|

2. Flexible connection: |

|

|

where: |

|

T |

torque [Nm] |

|

|

K a |

application factor |

|

|

K f |

wear-life factor |

|

|

K w |

application factor |

|

|

K m |

load distribution factor |

|

|

S v |

desired safety |

|

|

d |

shaft diameter [mm] |

|

|

N |

number of grooves [-] |

|

|

h |

height of groove |

|

|

s |

chamfer |

|

|

h st |

connection height h st = h - 2 s [mm] |

|

|

l f |

active key length [mm] |

Strength Check

p min ≤ p Ds

p min ≤ p Dh

where:

|

p min |

minimal calculated h/2 pressure [MPa] |

|

|

p Ds |

allowable pressure in shaft [Mpa] |

|

|

p Dh |

allowable pressure in hub [Mpa] |