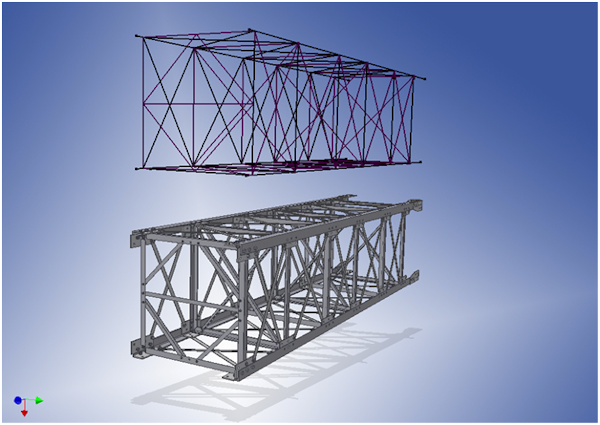

In the skeletal modeling method, you put all known factors into a skeleton file. Then you use it as a base for most of the subassemblies and parts that make up the assembly.

A skeleton file can contain any type of element in any combination. The following is typical information created in a skeleton file:

- Sketches Define the concept of the final product, or use as a layout of different areas of the assembly.

- Work geometry Defines important connection points, axial directions, and work planes that define assembly levels.

- Parameters Define important values for part size, angles for placements, and other known values for the design.

- Solids Define volumes for final assembly as a single part or for defining subareas of the design.

Advantages

- Simple assembly or component creation.

- Easy design modification.

- Reference common connections or critical locations from a single file.

Disadvantages

- Slight data volume increase.

- Additional creation of skeleton sketches.

Inventor commands

- Sketch blocks

- Sketch constraints

- Make Part

- Make Components

- Derive

- Adaptivity