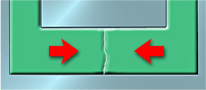

A weakness or visible flaw created when two or more flow paths meet during the filling process.

Holes or inserts in the part, multiple injection gates, or variable wall thickness where hesitation can occur can cause Weld lines. If the different flow fronts have cooled before meeting, they do not recombine well, and cause weakness in the molded part. A line, notch, and/or color change can also appear.

The quality of the weld line depends on the material type, the type and number of fillers, and the pressure and temperature at the weld line.

Move weld lines to areas where strength is of less importance and visual appearance is less obvious. Weld lines can be moved by changing:

- Gate position and dimension.

- Wall thickness.

Note: The Weld lines result in the Study Tasks pane do not show all weld lines if the model mesh is too coarse.

Related concepts