Add friction and complete the yoke-guide relationship

- In the browser, right-click Blade set.iam and click Flexible. By setting the assembly to Flexible, the assembly is placed into the welded group folder. Within that assembly the constraints are evaluated and the constraint between the yoke and blade causes the addition of a Revolution joint.

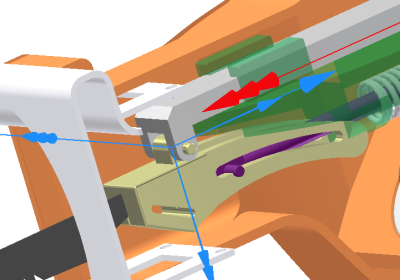

- As was mentioned earlier, the assembly has no friction so far. This step imposes friction on the prismatic joint. Right-click the Prismatic joint for the Guide and Scottish Yoke, and click Properties.

- Click the dof 1 tab. Click the joint forces command

. Click Enable joint force. Enter a Dry Friction coefficient of 0.1 and click OK.

. Click Enable joint force. Enter a Dry Friction coefficient of 0.1 and click OK. - Add a constraint to position the Scottish Yoke with respect to the crank assembly. Set the browser view to Model and expand the Blade set.iam node.

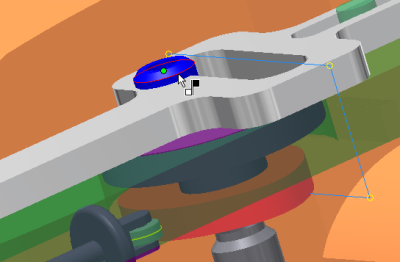

- Expand the Scottish Yoke node and click the Constraint command.

- In the browser, select Work Plane3 under the Scottish Yoke component.

- In the graphics region, select a circular edge of the Roller component that is part of the Crank cam assembly. A Point-Plane joint is added to reflect the constraint.

The resulting Point-Plane joint has five degrees of freedom and one constraint. This definition is enough to transfer motion without over constraining the model. Dynamic Simulation detects over-constrained conditions and helps you to resolve them.