A mold is a series of machined steel plates containing a cavity or cavities into which molten plastic is injected at high pressure. When the plastic cools, it solidifies into the shape of the cavity defined by the steel plates.

After you have modeled your part and are satisfied with the injection location and part design, you will design the mold. This will include the feed system and, if necessary, a cooling system.

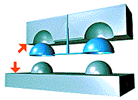

When you have oriented the model and specified a parting plane, you will specify the mold dimensions. You will define the dimensions of the mold, the mold offsets, the plate thicknesses, and the length and width of the mold that is required to fully enclose the model. Ensure there is enough room in your mold to accommodate runners and cooling channels. The red arrows in the following diagram highlight the two mold halves required to produce two hemi-spherical parts along with the associated feed system.