Overpacking in multi-cavity or family molds occurs when one part fills before another.

Overpacking might occur because:

-

One part is significantly larger than the other

-

The runners are unbalanced, so the flow lengths vary in parts with a similar size.

-

The pressures at the injection location of each part vary.

-

The runner system is poorly designed.

Overpacking can be avoided in multi-cavity or family molds by ensure that each part fills correctly as a single part. Once you have found the best injection location for each individual cavity, design the runner system so that all parts finish filling simultaneously. The Fill Time result will help you do this.

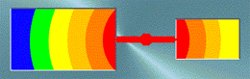

In the following diagram, the smaller part will fill first and will overpack because pressure must be maintained to fill the larger part.