Hesitation, which occurs when the melt flow slows down or stops along a particular flow path, can lead to asymmetrical and unpredictable flow patterns.

Hesitation

When the melt entering a cavity is filling a thin section and a thick section, it tends to fill the thick section first because this route is less resistant to flow. This can result in the melt in the thin section stopping or slowing significantly. Hesitation can reduce part quality due to variations in surface appearance, poor packing, high stresses and non-uniform orientation of the plastic molecules. If the hesitation enables the flow front to freeze completely, part of the cavity may remain unfilled, resulting in a short shot.

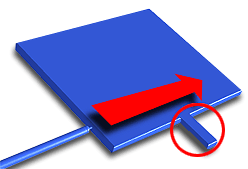

The melt cools more rapidly as it starts to slow down so the viscosity increases. In turn, this higher viscosity inhibits flow further, causing even faster cooling, so the problem is self-propagating. Hesitation can occur in ribs and in thin sections of parts that have significant changes in wall thickness. In the following diagram, the rib circled in red offers a higher resistance to flow because it is much thinner than the rest of the part.

What to do

The following animations show how hesitation in a part can be avoided by using a different injection location. When there is no alternative route available, the flow in the rib will be continuous and not hesitate, as shown in the second example.

Viewing the fill time and temperature results can help explain why the hesitation occurred. The fill time plot will show hesitation by a narrow spacing of fill time contours, and the temperature plot will show hesitation by a low temperature and a large temperature gradient.

-

Move the polymer injection location away from the area of hesitation so that the bulk of the cavity fills before the melt reaches the thin area. The absence of alternative flow paths will give less time for the polymer to hesitate.

-

Move the polymer injection location to a place that will cause greater pressure to be applied where the hesitation occurred. It is useful to have thin ribs/bosses as the last point to fill, so all the injection pressure is applied at this point.

-

Increase the wall thickness where the hesitation occurred, to reduce the resistance to flow.

-

Use a less viscous material (that is, a material with a higher melt flow index).

-

Inject more quickly to reduce the potential of hesitation time.

-

Increase the melt temp so that it flows into the thin area more readily.