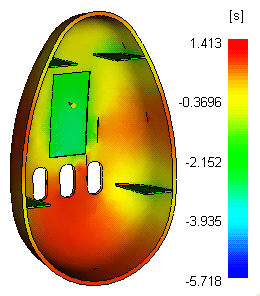

The Cooling time variance result shows the difference between the time it takes for polymer to freeze in any region of the part and the average time it takes to freeze in the entire part.

The average time to freeze is calculated on the basis of the surface area and the existing cooling channels. Areas that are plotted as positive values, which appear in red, take longer to freeze than the average time to freeze. Areas that are plotted as negative values, which appear in blue, freeze more quickly than the average time to freeze. Zero values in this result indicate the average time to freeze.

Using this result

Red areas demonstrate higher temperatures than the average part temperature, a sign indicating that the area will need more cooling.

Taken together, the Temperature variance and Cooling time variance results indicate places on the part that might require redesigning, such as changing the thickness of a wall or the inclusion of cooling devices in the mold (such as a bubbler), or positioning cooling away from fast cooling areas.

Cycle time predictions are based on 90 percent of the part thickness being frozen, which is the normal threshold for part ejection. The Cooling time variance result is based on the time required for every part of the model to freeze completely. Using this result, you can decide whether to extend the estimated cycle time so that critical areas of the part are properly solidified before ejection.

Things to look for

There are a number of part design options available to improve the uniformity of the part freeze time. Alterations usually have side effects so after making changes, you should check to see if other problems have been caused.

| Cooling time variance significantly low | Possible problems |

|---|---|

| Increase thickness in the area to increase time to freeze. | May cause a functional problem with the part. |

| Increase the melt temperature. |

|

| Cooling time variance significantly high | Possible problems |

|---|---|

| Decrease thickness in the area to decrease time to freeze. | May cause functional problems with the design or reduce structural strength. |