The injection time is the time it takes for the mold to fill completely.

When you set up a Fill+Pack analysis sequence, the software can be set to either calculate a machine injection time automatically, or on the basis of a user-specified value. By default, the injection time is calculated automatically.

(). In the Machine injection time section, either select the Automatic injection time check box to let the software automatically calculate the injection time, or clear the check box and enter a numeric value as the specified injection time.

(). In the Machine injection time section, either select the Automatic injection time check box to let the software automatically calculate the injection time, or clear the check box and enter a numeric value as the specified injection time. Automatic injection time

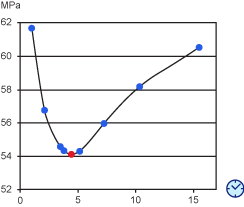

If you set the injection time to Automatic, the analysis finds the injection time which gives the lowest injection pressure. The following graph shows the results from nine analyses on the same part. The blue points represent the analyses where the injection time was set to a particular value. The red point represents the analysis where the Automatic injection time check box was selected, which shows the lowest possible injection pressure for the part.

Injection pressure as a function of time

The variation of injection pressure against injection time has two influences. Firstly, as the injection time increases from zero, the pressure required to force the molten plastic through the part decreases. Secondly, as the injection time increases, the polymer temperature decreases due to heat transfer to the mold, which causes the viscosity and frozen layer thickness to increases, which in turn increases the injection pressure.

Specified injection time

If a specified injection time is entered, the Summary lists an actual injection time that is slightly higher than the value entered. The extra time is to account for material compressibility.