Some mold surfaces must be tapered so that the plastic part can be ejected from the mold when it has cooled sufficiently.

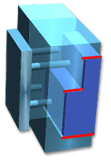

Untapered mold walls

The walls of the mold in the following diagram, which are marked with red, are not tapered. When the ejector pins push the finished part out of the mold, the force applied must overcome the friction between the mold wall and the plastic part.

As shown in the following animation, when the mold walls are not tapered, the frictional resistance continues throughout the ejection process. Plastic parts that do not have tapered walls can be impossible to eject from the mold. Even if the part is ejected, the surface can be scuffed in the process, making the part visually unacceptable.

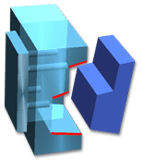

Tapered mold walls

The walls of the mold in the following diagram, which are marked in red, are tapered.

As shown in the following animation, when the ejector pins push the finished part out of the mold, there is an initial resistance due to friction which then is reduced to zero when the part is moving. Depending on the surface finish of the part, a draft angle of 1.5º for highly polished surfaces up to 6º-8º for a leather like surface will enable the part to be easily ejected from the mold.