Heated runners are a type of hot runner in which heat is supplied to maintain the material in a molten state. Hot runner systems can be internally heated or externally heated.

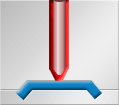

- Internally heated runners

-

Internally heated runner systems have annular flow passages, with the heat being furnished by a probe and a torpedo located in the passages, as shown in the following diagram. This system takes advantage of the insulating effect of the plastic melt to reduce heat transfer loss to the rest of the mold.

The advantags of an internally heated runner system are improved distribution of heat and better temperature control. The disadvantages of this type of heated runner system are higher costs and a more complicated design.

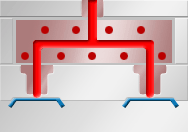

- Externally heated runners

-

Externally heated runner systems consist of a cartridge-heated manifold with interior flow passages, as shown in the following diagram. The manifold is designed with various insulating features to separate it from the rest of the mold, thus reducing heat loss.

The advantage of an externally heated runner system is its sophisticated heat control. The disadvantages of this type of heated runner system are higher costs, a more complicated design, and the thermal expansion of various mold components that has to be taken into account.