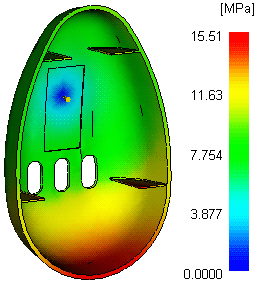

The Pressure drop result uses a range of colors to indicate the region of highest pressure drop through to the region of lowest pressure drop. This result indicates how much pressure is necessary to fill the different areas of the part.

As shown in the following diagram, the color at each place on the model represents the drop in pressure from the injection location to that place on the model at the moment that place was filled, that is, the pressure required to force material to flow to that point.

Using this result

The Pressure drop result is one factor that is used to determine the Confidence of Fill result. If the pressure drop is greater than 80 percent of the current value set for Maximum machine injection pressure in the Analysis Wizard Process Settings page, this causes a yellow confidence of fill. If the pressure drop reaches 100 percent of the current Pressure Limit setting, the Confidence of fill result for this area is red.

If the default value of 180 MPa for the Maximum Injection Pressure Limit is higher than the actual molding machine capacity, the Confidence of fill result will be better than is actually expected. Some molding machines can inject material at up to 200 MPa so a knowledge of the typical performance of the machines used in production can help you determine the viability of the Pressure drop result.

Things to look for

- Increase the maximum injection pressure to improve the Confidence of fill.

- Move the polymer injection locations closer to the problem area or add additional injection points to improve the likelihood of all sections of a part filling.

- Alter the part geometry; complex and thin geometry can cause filling difficulties that require high injection pressure to complete the filling.

- Select a different material with a higher melt flow rate so that less injection pressure is required to fill the part.

- Increase the melt temperature to reduce the viscosity of the melt and enable the melt to flow into the mold more easily.