The two-plate mold is the most commonly used mold type. Compared to the three-plate mold, the two-plate mold is cheaper and simpler to make and has a lower cycle time.

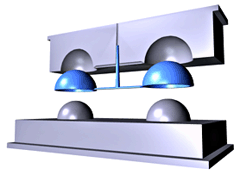

Before you design a multi-cavity mold, you should analyze the single part to determine the gate location. In a two-plate mold, the runners and gates must be in the parting plane so they can be ejected when the mold opens. It is possible to use a two-plate mold for multi-cavity or family molds, but only if the parting plane can be aligned with the gate, as illustrated in the figure below.

When designing a multi-cavity mold, it is important that you design the runners so that the flow of polymer is balanced. With some multi-cavity molds it might not be possible to balance the flow of material using a conventional two-plate mold, so you might have to use a three-plate mold, or a two-plate mold with hot runners, instead.