There are a number of factors to consider when designing the feed system, including the gate locations, the number of cavities, the shape of the runner system components, and flow balance.

The first step in designing the feed system is to determine the gate locations for each part in the mold. The rest of the components will fit into place depending upon each gate location. The objective when designing the feed system is to design it with balanced flow so that each part in the mold fills at the same rate. The creation of a well-balanced feed system requires careful consideration the following elements:

- Single-cavity, multi-cavity, or family mold

- Cavity layout

- Location of the sprue

- Runner system layout

- Shape of the sprue, runners, and gates

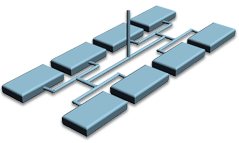

In general, make runners as short as possible, with the lowest possible shot weight. In the following diagram, the flow length for every part is the same. This is a naturally balanced runner system.