The Confidence of fill result displays the probability of plastic filling a region within the cavity under conventional injection molding conditions.

This result is derived from the pressure and temperature results.

Using this result

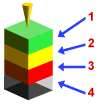

The colors displayed in the Confidence of fill result indicate the following:

- Will definitely fill.

- May be difficult to fill or may have quality problems.

- Will be difficult to fill or will have quality problems.

- Will not fill and results in a short shot.

Confidence of Fill color codes

If the Confidence of fill result shows that your part will have medium or low confidence of fill, use the Results Adviser dialog to open the relevant Help topic and find out how to fix the problem.

Things to look for

If the cavity does not fill and results in a short shot, changes must be made to the design, injection location, choice of plastic, or processing conditions. To ensure the finished part is of good quality, the cavity must also be adequately packed with plastic. You must therefore determine not only whether the part will fill, but also whether a good quality part can be made.

When determining whether a good quality part can be molded, consider which colors are visible and how much of each color appears. You should also look at the Quality Prediction result.

The Adviser uses these two items of information to calculate the risks of producing this part on the following sliding scale.

| All green | The part is easily filled and part quality should be acceptable. |

| Some yellow | The part may be difficult to mold or quality may not be acceptable. As the percentage of yellow increases, the difficulty in molding the part will increase and the part quality will decrease. |

| Some yellow and red | The part will be extremely difficult to fill or quality is more likely to be unacceptable. As the percentages of yellow and red increase, the difficulty in molding the part will increase and the part quality will decrease. |

| Any translucent | The part cannot be molded because a short shot will occur. |