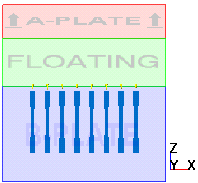

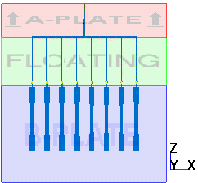

The runner modeling functionality always assumes that the parting plane corresponds to the global XY plane. The sprue and drops are then created perpendicular to this parting plane. In the case of a 3-plate mold however, to create a runner system with the correct orientation you need to use a parting plane (XY plane) that is parallel to the actual mold parting plane. The drop runners will be created at right angles to this plane. The required procedure is described below.