The Grow from result, which is produced by a Fill analysis, shows the areas that are filled from each gate in multi-gated parts so that you can determine whether the flow within the part is balanced.

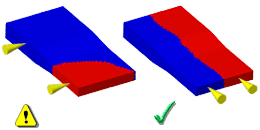

A Grow from result that shows uniform filling will be balanced. A Grow from result that shows that different gates are trying to fill the same section of the part, will be unbalanced. Non-uniform filling (left) and uniform filling (right) are shown in the following diagrams.

The Grow from result uses numbers to identify the gate in which the polymer was injected. When the Fill analysis is complete, the Grow from result indicates the filling pattern of the part and shows which areas of the part were filled from which gate.

Using this result

A Gate Location analysis can determine more appropriate gate locations on your model, and the Grow from result can be improved in a number of ways. Alterations usually have side effects so after making changes, you should check to see whether other problems have been caused.

| Problem | Resolution |

|---|---|

Unbalanced flow patterns can be caused by:

|

|

| A weld or meld line is in a sensitive area. |

|

Things to look for

A result that shows an equal distribution of colors will also have a uniform filling pattern and be balanced. If the distribution of colors is not equal, then the flow is unbalanced.