The Orientation at skin result provides a good indication of how molecules will be oriented on the outside of the part, showing the average principal alignment direction for the whole local area at the end of filling.

Because the melt freezes very quickly when it contacts the mold for the first time, the velocity vector provides the most probable molecular orientation at the skin.

The magnitudes of these vectors are normalized to one and are displayed multiplied by the given scale factor. Skin orientation is determined by the velocity direction when the melt front first reaches a given location.

Using this result

The Orientation at skin result is useful for estimating the mechanical properties of a part. For example, the impact strength is typically much higher in the direction of molecular orientation at the skin. When using fiber-filled polymers, the tensile strength is also higher in the direction of orientation at the skin because the fibers on the surface are aligned in that direction. The skin orientation generally represents the direction of strength. For plastic parts that must withstand high impact or force, the gate location can be designed to give a skin orientation in the direction of the impact or force.

The linear shrinkage of a part also depends on the skin orientation. For unfilled polymers, the shrinkage in the direction of the skin or flow orientation is greater than in the direction of the core or transverse orientation. This situation may be reversed when using fiber-filled polymers due to the low shrinkage and stiffness of the fibers in the direction of skin orientation.

Compare the Orientation at skin result with the Fill time result to identify unbalanced flows in the part.

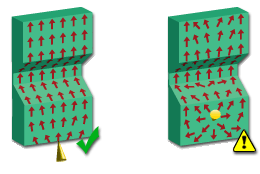

It is important to orientate the molecules correctly to ensure the mechanical quality of a hinge. The injection locations must be placed in positions that produce a consistent molecular orientation, as shown in the following diagram on the left. The diagram on the right shows inconsistent molecular orientation, which leads to lower part quality.

Things to look for

- Unbalanced flow

- Inconsistent orientation