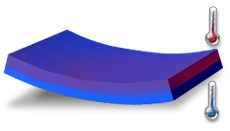

Warpage occurs when there are variations of internal stresses in the material caused by a variation in shrinkage.

Warped parts may not be functional or visually acceptable.

Causes

- Non-uniform cooling. Temperature differences from one side of the mold to the other can lead to layers freezing and shrinking at different times and generating internal stresses.

- Inconsistent shrinkage. Resulting from:

- Material variations such as property variations, varying moisture content, inconsistent melt and pigmentation;

- Process conditions variations such as inconsistent packing and varying mold and melt temperatures;

- Machine variations such as a damaged check ring and unstable controller.

Remedies

-

Minimize differential shrinkage.

-

Minimize orientation effects. Position gates for unidirectional flow, and modify part thickness.

-

Change the part geometry. Add features such as stiffening ribs to the design. Change the part design to avoid thick sections and reduce the thickness of any features that intersect with the main surface.

-

Use thinner wall sections with ribs. Thicken only those wall sections that require extra material for structural stability and that cannot be strengthened using another method.

-

Change the material. Semi-crystalline have naturally higher shrinkage and hence are more prone to warpage.

Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design specification.