Uniform cooling helps you achieve effective heat transer .

Effective heat transfer is achieved when the following conditions are met:

- The coolant flow is turbulent.

- The area of the cooling surface is great enough.

- The temperature difference across the coolant/metal interface is 2–5°C.

- The inlet/outlet temperature of the coolant varies between 2–3°C.

When these conditions apply, the temperatures on the mold surface are determined by heat transfer through the metal to the coolant/metal interface. This is a function of the conductivity of the metal and the geometry of the mold.

Surface temperatures are controlled by the position of the cooling circuits relative to the surface of the mold.

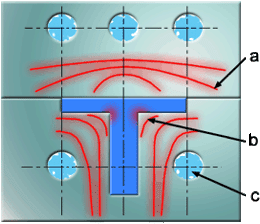

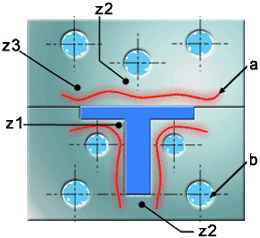

In the following diagram, the surface temperature is highest at the internal corners and lowest on the thin top bar. To achieve a uniform temperature, the cooling channels must be placed as near as possible to hot spots and away from surfaces that have a tendency to run cold.

where:

- a - Isotherms

- b - Hot spot

- c - Cooling circuit

where:

- a - Isotherms

- b - Cooling circuit

- z1, z2 and z3 - Zone 1, zone 2, and zone 3