In a two-plate mold with hot runners, the material remains in a molten state through the sprue, runners, and gate and only starts to freeze when it enters the cavity.

Hot runners are ideally suited to multi-cavity molds where the molded parts are small. If there are many small parts, a conventional runner system can waste a lot of material, particularly if no regrind of materials is possible. In a two-plate mold with hot runners, once the material in the cavities has frozen and the mold has been opened, only the molded parts and any cold runners are ejected. When the mold is closed again, the molten polymer that is still in the runners fills the cavity again. Runners in a mold can be a combination of both hot and cold runners.

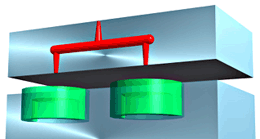

Two-plate molds with hot runners can be used as an alternative to a three-plate mold because the runners don't need to be ejected. In the following diagram, the injection location for this mold has been placed at the center of the cavity, to avoid marking the part on a visual side; therefore, the runners cannot be positioned on the parting plane.

The advantages of hot runner systems tend to outweigh the disadvantages when producing large quantities of high-quality parts. Sometimes the best results can be achieved by using a combination of hot and cold runners.

Advantages of hot runners

-

Less material waste and no regrinding

-

Less obvious gate marks

-

Degating may not be required

-

Shorter cycle time

-

Greater control over the filling of the mold and flow of the polymer

Disadvantages of hot runners

-

Higher initial setup costs

-

More difficult to change material color

-

More prone to breakdown, especially the heating control system

-

Not practical for thermally sensitive materials