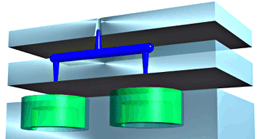

A three-plate mold is used when part of the runner system is on a different plane to the injection location.

The runner system for a three-plate mold sits on a second parting plane parallel to the main parting plane. This second parting plane enables the runners and sprue to be ejected when the mold is opened. In the following diagram of a three-plate mold, the runners will be ejected separately to the cavities.

The runner system can be placed on a different plane from the injection location in the following situations:

-

The mold contains multiple or family cavities

-

A complex single cavity mold requires more than one injection location

-

The injection location is in an awkward position

-

Achieving a balanced flow requires the runner to be outside the parting plane

You can use a two-plate mold with hot runners to overcome these problems, but three-plate molds have some advantages over hot runner molds.

Advantages of three-plate molds

-

Cheaper to build than a hot-runner mold

-

Less likely to break down than a hot-runner mold

-

Thermally sensitive materials are less likely to degrade

Disadvantages of three-plate molds

-

Higher cycle time due to ejection of the runner system

-

More material is wasted

-

Greater injection pressure is required to fill the mold