In an injection-compression molding process, a pre-set amount of plastic material is injected into an open cavity, and then the cavity is compressed to complete filling and packing.

Injection-compression is advantageous for production of precision parts that require low residual stresses, such as optical discs and high-precision moldings. Conventional injection molding may not be able to meet product design requirements for these parts because thermoplastics are inherently difficult to process due to their pvT characteristics and high viscosity.

Injection-compression molding process

Injection-compression molding is sometimes called coining, stamping, compressive-fill, or hybrid molding. The injection-compression molding analysis simulates the following special characteristics of the Injection-compression molding process:

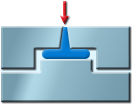

- Injection phase

- During this stage, the mold cavity thickness is designed to be larger than the target part thickness, in order to allow plastic to flow easily to the extremities of the cavity. Because the plastic flows easily, it can do so under relatively low pressure and stress.

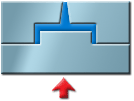

- Compression phase

- During or after filling, a compressive force reduces the mold cavity thickness, forcing the resin into the unfilled portions of the cavity. This produces a more uniform packing pressure across the cavity. This results in more homogeneous physical properties and less molded-in stresses compared to conventional injection molding.

Injection phase (above), Compression phase (below)

Features

Injection Compression provides:

- Independent control of the injection and compression units.

- Two-stage press control: speed control and force control.

- Open and close control for the polymer injection location and valve gate.

Injection-compression helps you to:

- Minimize the press force (clamp force) for compression.

- Minimize the injection pressure.

- Minimize shrinkage, warpage and residual stress.

Note: The compression effect is applied only to surface elements. In general, press force control needs more computational time than press speed control.