Co-injection molding involves injection of two dissimilar materials. Because of this, co-injection has some special advantages, as well as some potential molding problems. The Co-injection analysis helps you overcome the potential problems and leverage the advantages, by helping to optimize process control strategies and enhance part quality.

Co-Injection analysis simulates the sequential injection of skin and core plastic materials. Sequential co-injection processes have two barrels and one nozzle in an injection molding machine.

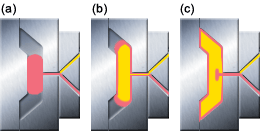

Co-injection process

.(a) The skin plastic is injected into the mold first. (b) The core plastic then is injected. (c) finally, the skin plastic is injected again, to purge the core material from the sprue .

The skin plastic is the material that is expected to be deposited on the cavity wall over the entire surface of the part. The core plastic displaces the skin plastic at the hot core, pushing it to fill the rest of the cavity. The end product is a sandwich-like structure, with the core plastic in the middle and the skin plastic on the surfaces of the part.

Co-injection molding takes advantage of a characteristic of injection molding called fountain flow. As the cavity is filled, the plastic at the melt front moves from the center line of the stream to the cavity walls. Because the wall temperature is below the transition temperature (freeze temperature) of the melt, the material that touches the walls cools rapidly and freezes in place. This provides insulating layers on each wall, through which new melt makes its way to the melt front.

Advantages and applications

The advantages of this process are:

- The combination of two material properties into one part.

- The maximization of the overall performance/cost ratio.

Examples of co-injection applications include:

- The use of plastic regrind as the core material, while maintaining surface finish quality by using virgin plastic as the skin material.

- The use of a core material that is thermally more stable, to increase the thermal resistance of a part.

- The use of a high melt-flow index plastic as the core material, to reduce the overall clamp force.