The Sink marks, index is an indication of the potential shrinkage due to a hot core.

It is calculated for each element at the instant when local pressure has decayed to zero during the packing stage, and reflects how much material is still melt and left unpacked. Higher Sink marks, index value shows higher potential shrinkage. However, whether or not the shrinkage would result in sink mark depends on geometry characteristics.

The Sink marks, index generated indicates the likely presence and location of sink marks (and voids) in the part.

Using this result

The Sink marks, index indicates a degree of severity of depth as affected by the material, part geometry, position relative to the injection location and mold filling conditions. Changing any of these would allow you to determine its contribution to the sink marks severity. Generally, if the thickness of a rib is less than or equal to 60% of the main wall section, then there are likely to be no significant sink marks.

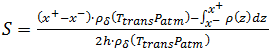

When the local pressure has decayed to zero during the packing and cooling stage, the Sink marks, index for the part is calculated as follows:

-

- is the transition temperature of the polymer

-

- is the upper interfacial location where the temperature of the polymer is at the b5 value in the 2-domain Tait pvT model

-

- is the lower interfacial location

-

- is the solid density of the polymer

-

- is the atmospheric pressure

-

- is the half-gap thickness

The terms of the Sink marks, index equation can be interpreted as

((ideal mass of the liquid polymer) − (actual mass of the liquid polymer))/(ideal mass of the total thickness)

where the ideal mass is determined from the solid density value in the material properties, and the actual mass is determined from the pvT data.

The integration term in the Sink marks, index equation adds the density of the layers at the point where they become frozen. If the pressure at that point is high, then it is possible for the calculated total actual mass to be higher than the ideal packed density resulting in a negative Sink marks, index value. Negative Sink marks, index values therefore indicate overpacking in that area of the part. If the Sink marks, index is high, then it is possibly because a significant portion of the melt is freezing under zero, or low pressure. The larger the volume that freezes under low pressure, the higher the Sink marks, index and the greater the likelihood of a sink mark.

If it is not possible to remove or reduce a sink mark to the design criteria, you can conceal it. This can be done by adding a design feature, such as a series of serrations on the area where they occur.

What to do next

- Alter part design to avoid thick sections and reduce the thickness of any extrusions, or conceal the sink marks within the design.

- Increase the packing pressure/packing time.

- Relocate the gate to or near a thicker section. This allows these sections to be packed before the thinner sections freeze.

- Increase the size of gates and runners to delay the gate freeze-off time. This will allow more material to be packed into the cavity.

- Decrease the melt and mold temperature.

- Use a material with a lower viscosity.