This topic describes how to create and apply heat exchanger materials. Several application examples are presented to illustrate the three different modes of heat exchanger operation.

For modeling guidelines and results extraction, click here.

To assign a Heat Exchanger Material

- Open the Material quick edit dialog. There are several methods:

- Left click on the part, and click the Edit icon on the context toolbar.

- Right click on the part, and click Edit...

- Right click on the part name under the Materials branch of the Design Study bar, and click Edit....

- Click Edit in the Materials context panel.

- Select one or more parts.

- Select the database from the Material DB Name menu.

- Select Heat Exchanger from the Type menu.

- Select the material from the Name menu. (There are several commercially-available heat exchanger models included in the database.)

- Select the heat exchanger inlet (a) and outlet (b):

- Click Apply.

To Create and Edit a Heat Exchanger Material

- To open the Material Editor, click Material Editor on the Materials context panel.

- Click the List button.

- Right click on a custom database, and select New material. Select Heat Exchanger. Specify a Name.

- Click the property button that is to be defined.

- The two properties that define a heat exchanger are Flow and Heat Transfer. For each property, select the variation method, enter the appropriate value and units, and click Apply.

- Optionally, click Save.

- Click OK.The new material is available when the Materials quick edit dialog is opened.

Property: Flow

Specify the amount of fluid that moves through the heat exchanger device. Use either a constant value or a fan characteristic (pressure-flow curve).

Constant:

Enter the flow rate Value and appropriate units.

Fan Curve:

Specify the Flow Rate and Pressure Head values. This information is usually supplied by the manufacturer.

Property: Heat Transfer

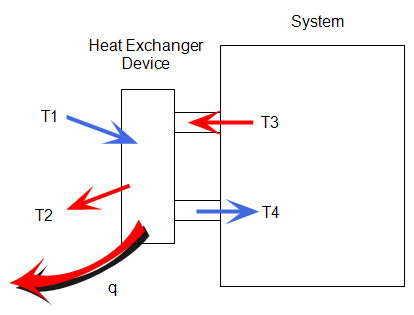

Define the thermal behavior of the heat exchanger device. The following heat exchanger device schematic illustrates the conventions used in the variation methods descriptions:

There are several property variations to simulate different physical models:

Heat Exchanger

The Heat Exchanger mode removes heat from the working fluid. Conceptually it is similar to a physical heat exchanger device.

Specify the following:

- The input Temperature, T1. In many cases, T1 is the ambient air temperature.

- The Heat Capacity of the heat exchanger device. The is the amount of heat required to change the temperature by 1 degree.

Temperature Change

The Temperature Change variation simulates a known temperature rise or drop (T3 - T4).

Heat input/Extraction Rate

The Heat input/Extraction rate variation simulates the addition or removal of heat to the working fluid. It is an ideal way to simulate data center CRAC devices. The heat extraction rate is often supplied by CRAC manufacturers.Be sure to specify a temperature or film coefficient boundary condition on the system. Otherwise the thermal solution is unbounded, and may produce unrealistic temperatures. The result is solution divergence.

Air Conditioner

This method simulates an air conditioner that delivers air to the environment at a prescribed temperature (the Set Point Temperature). This is T4, the air temperature leaving the heat exchanger device.

Use this method to simulate air conditioner and CRAC units that deliver air at a constant temperature. At the conclusion of the simulation, the Heat Absorbed output quantity (in the Heat Exchanger tooltip) indicates the performance of the device.