The Summary File contains tabulated minimum, maximum, and average nodal values for selected variables. Global summary calculations at every inlet and outlet for mass flow, bulk pressure, temperature, and Reynolds number are provided. Wall heat transfer, the global energy balance and the fluid forces are reported for the entire model.

Analysis run-time statistics and the amount of RAM used are listed.

The summary file has a ".sum" extension, and can be viewed in any text editor.

The analysis calculation units and the units for every variable are included in the file.

Openings

All velocity boundary conditions are labeled “inlet,” and all pressure boundary conditions are labeled “outlet.” This is for book-keeping purposes, and is not based on the direction of the flow into or out of the model.

For each opening, the following values are reported:

- Mass Flow Rate (in or out)

- Volume Flow Rate (in or out)

- Reynolds Number

- Bulk Pressure (inlet or outlet)

- Bulk Temperature (inlet or outlet)

- Mach Number (inlet or outlet)

- Total Mass Flow (in or out)

- Total Volume Flow (in or out)

For pressure-driven flows, (with a specified pressure at the inlet and outlet), the summary file will report that there are zero inlets, and two outlets. The physical inlet will have a positive mass flow rate, and the physical outlet will have a negative mass flow rate. Also note that the “Total Mass Flow In” and the “Total Mass Flow Out” will be 0. This is because there are no specified velocity conditions (no labeled inlets), and the total mass flow from the labeled outlets cancels (one is positive, and the other is negative).

Note about Reynolds Number:

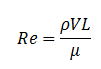

The basic form Reynolds number is computed as:

- V = average velocity through the cross-section

- L = characteristic Length

= fluid density

= fluid density  = fluid density

= fluid density

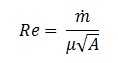

The average velocity across a cross-section is computed as:

= mass flow rate

= mass flow rate - A = Cross-sectional area

The characteristic length, L, is computed as the square root of the cross-sectional area:

The resultant equation for the Reynolds number is then:

Temperature Statistics

For analyses with heat transfer, statistics for temperature distribution are included in the summary file. These statistics show how much (as a volume percentage) of the model has a temperature within a given range.

Summary of Fluid Forces on Walls

The cumulative force components are reported in the Summary file as Shear and Pressure results. These values are the summed force values from all walls in the model. Use the Wall Calculator in the Results task dialog to compute forces at individual surfaces.

Shell Forces

If an analysis contains shells (solid surface obstructions), then force, temperature, and heat transfer information for each surface is listed in the summary file.

Energy Balance

| Line | Fluid Energy Balance Information: |

| 1 | MdotIn x Cp x (TOut - TIn) |

| 2 | (Numerical) Energy Out - Energy In |

| 3 | Heat Transfer from Wall to Fluid |

| 4 | Heat Transfer Due to Sources in Fluid |

| 5 | Sum Radiant Heat Transfer to Fluid Walls |

| Solid Energy Balance Information: | |

| 6 | Heat Transfer from Exterior to Solid |

| 7 | Heat Transfer Due to Sources in Solid |

| 8 | Heat Transfer From Fluid to Solid |

Line 1: The physical difference in energy in the fluid from the outlet to the inlet.

Line 2: The difference in energy in the fluid from the outlet to the inlet. This is the sum of the residuals over the entire fluid domain. It represents the total energy needed to sustain all of the fluid boundary conditions. This should match up with the quantity:  (Line 1).

(Line 1).

Line 3: This is how much energy the fluid picked up from heat transfer boundary conditions on the wall, and is the sum of the residuals at all of the wall nodes, including those nodes on the interface of the solid materials. In the case where all of the external fluid walls (not touching any other volume or surface) are adiabatic, this represents the amount of energy the fluid gets from the solid materials. If there are thermal boundary conditions on these external fluid walls, Line 3 will include those conditions as well as the energy being transferred from the solid materials.

Line 4: This is the summed energy from heat sources in only the fluid elements/volumes.

Line 5: The residuals calculated in Lines 2-4 and Lines 6-8 do not include the radiative fluxes. This line sums the radiative fluxes from every wall surface.

Line 6: This is how much energy is transferred to (or from) the solids to (or from) an exterior boundary. This is the sum of the residuals on the external faces of the solid materials. These are faces that do not touch any other material. In certain cases, where the solid material has say a heat generation applied to it and some external faces, this Line may contain a finite number which is the sum of the residuals on these external nodes. In this case, this number can be interpreted as the energy that would seep into the environment from that material. In the case where the external faces have a thermal flux-type condition or a specified temperature, this Line represents the amount of energy needed to sustain those boundary conditions.

Line 7: This is the summed energy from the heat sources in only the solid material elements/volumes.

Line 8: This is the energy that crosses the interface of the solid materials into the fluid elements. For adiabatic fluid external walls, this value should match up with Line 3.

For the Fluid Energy Balance, the following values should match:

Energy Out - Energy In = Heat Transfer from Wall to Fluid + Heat Transfer Due to Source in Fluid + Radiant Heat Transfer to Fluid Walls

or

Line 2 = Line 3 + Line 4 + Line 5

For the Solid Energy Balance, the following values should match:

Heat Transfer Due to Sources in the Solid = Heat Transfer from Exterior to Solid + Heat Transfer From Fluid to Solid + (some radiation)

or

Line 7 = Line 6 + Line 8 + (some radiation)

For radiation calculations, Line 8 will be larger than Line 6 because the radiative energy leaving the solids is not included.

Why don’t they exactly match? We are summing the residuals of the energy equation at every node in the model. If the energy equation is not converged, there will not be a balance. Even at convergence, the energy balance may still contain some errors due to numerical roundoff and mesh inaccuracies.

Further, note that the goal of Autodesk Simulation CFDis to obtain the most accurate solution in terms of temperature. Hence, the Autodesk Simulation CFD solver is not using the energy balance to determine the best solution, but it is looking directly at the energy equation and the temperature solution, optimizing for the best temperature solution. If the energy equation was formed based on fluxes, you would always get an energy balance even for a non-converged energy solution. However, balancing these fluxes would require you to smear or diffuse the temperatures to maintain this energy balance. This heat flux balancing would cause temperature gradients to be less steep. In Autodesk Simulation CFD, the temperature gradients are not artificially forced to conform to a flux or energy balance and therefore would maintain the steepness that the mesh and discretization would support. Since it is usually the temperatures that constrains the design, a more accurate solution of local temperatures would be desirable.

Can you get an energy balance in Autodesk Simulation CFD? Yes, but it may require a finer mesh and several 100 or more iterations. What we have found is that adding the extra mesh and iterations may not change the temperature more than a few tenths or even hundredths of a degree, but it may change the energy balance by 20% or more.

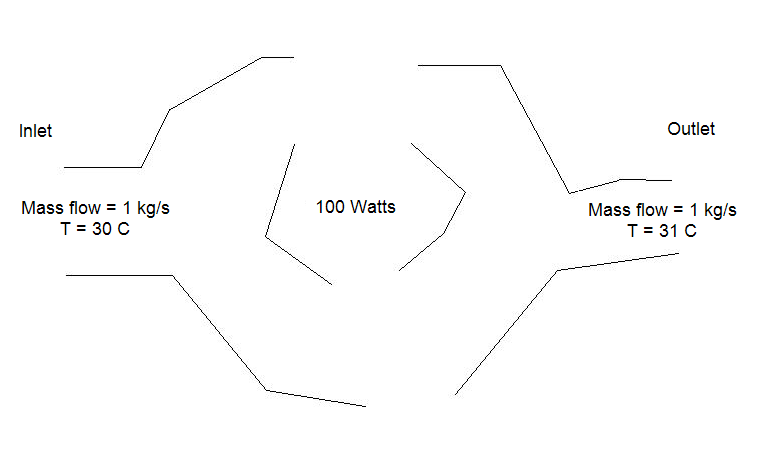

As an example, for the heat transfer problem in the figure below, the expected temperature rise from inlet to outlet is 1 degree C with a mass flow of 1 kg/s and the energy input is 100 Watts (specific heat of the fluid is 100).

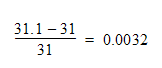

If the outlet temperature predicted by Autodesk Simulation CFD is 31.1 C, the error in the energy balance is 10%. However, the error in the temperature solution is:

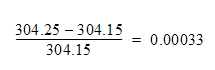

So, the error in the temperature solution is less than 1%. Furthermore, the temperature matrix is formed as an absolute temperature, so the real error in the temperature solution is:

Hence, the temperature solution has an error of 0.03%.