Many models constructed in Pro/Engineer consist of just the physical solids (the pipe wall, for example). There are three methods of creating the internal flow volume:

- Manually create it using tool within Pro/Engineer.

- Create capping geometry at the openings. This method is described in this topic.

- Create the void fill in the Autodesk Simulation CFD environment using the Geometry Tools. (Note that this method is not available when launching with the Mechanica method.)

Example of cap creation in Pro/Engineer

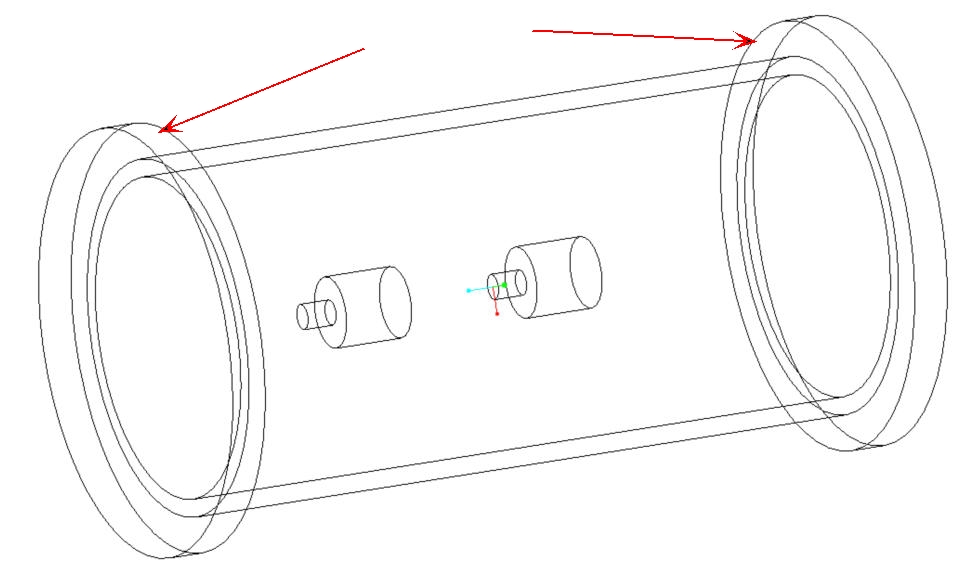

In the following example, the pipe wall and two internal parts were created in Pro/Engineer:

![]()

To prepare this for a flow analysis, simply add a cap to both ends of the pipe:

![]()

The Pro/Engineer geometry shown above consists of five parts: the pipe wall, the two internal components, and the two end caps. In this example, the caps are constructed using the inner diameter of the pipe wall, and extruded into the pipe. Alternatively, the caps could have been extruded out of the pipe, or have been built using the outer diameter of the pipe wall.

When brought into Autodesk Simulation CFD, the internal volume is automatically created:

![]()

The two internal parts are automatically cut from the newly created flow volume.

Mechanica-Specific Guidelines

Components built in Pro/Engineer must not interfere, so care must still be taken to eliminate part interferences from the Pro/Engineer model.

There are a few guidelines that should be observed when launching with the Mechanica method. (The Granite method does not require these guidelines):

- Parts that are inside of the void must not protrude through the outer wall of the geometry. If this occurs, the void filling will fail. This is shown:

- When using the Mechanica launch method, end caps must not extend beyond the geometry surrounding an opening. In this pipe example, the cap must not extend beyond the outer diameter of the pipe. An example that will fail is shown:

- Note that this void fill successfully when using the Granite launch method.