What Does a Controlled Temperature Do?

- A controlled temperature can be assigned to nodes, surfaces, or parts in a model. If multiple nodes are selected, each node will have the controlled temperature parameters assigned to it. A surface controlled temperature assigns the temperatures to each node on the selected surface. A part controlled temperature assigns the controlled temperature to each node of the selected parts.

- In a steady state heat transfer analysis, a controlled temperature is used to fix a node to a certain temperature throughout the analysis. The heat is transferred to the node on the model through an element with a thermal stiffness specified in the Stiffness field. The heat flow will be equal to the product of the stiffness and the difference of the magnitude of the nodal controlled temperature and the calculated temperature for that node. A high stiffness value will cause the node on the model to approach the magnitude of the applied nodal temperature. A low stiffness means that the temperature of the node on the model could be significantly different than the magnitude of the controlled nodal temperature. Check the temperature results to decide if the stiffness value was appropriate.

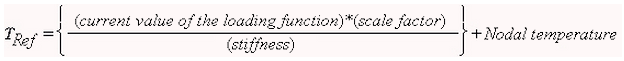

- In a transient heat transfer analysis, a controlled temperature can be used to control the temperature of a node throughout the analysis. The magnitude of the controlled temperature at any given time is calculated as:

where:

- TRef is the controlled temperature (temperature of the ambient source/sink),

- The loading function is the Factor defined for the load curve (in the Load Curves screen),

- The scale factor is the Scale value defined on the Controlled temperature dialog box,

- The stiffness is the Stiffness defined on the Controlled temperature dialog box,

- Nodal temperature is the Magnitude defined for the Controlled temperature.

Note: Although the scale factor and stiffness appear to cancel each other in the equation for TRef, this does not indicate that any arbitrary value can be used for the stiffness and scale factor. The stiffness value controls the rate of heat transferred from the ambient (TRef) to the node, so the stiffness must be set appropriately (high in this case). Referring to the equation, the easiest way to control the temperature of a node versus time is to add a nodal controlled temperature of magnitude zero and a scale value equal to the stiffness value. Then assign a load curve with a factor equal to the desired temperature throughout the analysis. For example, if the load curve factor at t = 2 seconds is 150, the scale factor and stiffness both defined as 1E8, and the controlled temperature magnitude defined as zero, then the nodal temperature at 2 seconds will be 150, the resultant of the prior equation: Tref = (150 * 1E8 / 1E8) + 0 = 150. - In a transient heat transfer analysis, a controlled temperature can be used to control the temperature of a node throughout the analysis. The magnitude of the controlled temperature at any given time is calculated as:

Apply a Controlled Temperature

If you have nodes, surfaces, or parts selected, you can right-click in the display area and select the Add pull-out menu. Select the Nodal Controlled Temperatures, Surface Controlled Temperatures, or Part Controlled Temperatures command, respectively. You can also access this command via the ribbon (Setup  Thermal Loads

Thermal Loads  Controlled Temperature).

Controlled Temperature).

Specify the magnitude of the controlled temperature that will be applied to each selected object in the Magnitude field and specify the stiffness of the controlled temperature in the Stiffness field. Use a large stiffness value to fix the node at the value entered in the Magnitude field (2-3 orders of magnitude higher than the conductivity of the materials in your model).

If you are performing a transient heat transfer analysis and want to vary the temperature of the nodes throughout the analysis, activate the Varies with Time check box. Specify the load curve that will control the magnitude of the nodal controlled temperature throughout the analysis. The load curve must be defined in the Analysis Parameters dialog box. Specify the scale for the controlled temperature in the Scale field. Refer to the discussion above for details on how this affects the temperature of the node.

If you want the controlled temperature to become active in the middle of the analysis, specify this time in the Activation Time field. Until this time, the controlled temperature will have no effect on the model. At the activation time the load curve will start at the factor at time 0 and continue until the analysis duration has ended.

- For a controlled temperature to be used properly during the analysis, a Boundary temperature multiplier must be assigned in the Multipliers tab of the Analysis Parameters dialog box. The Boundary temperature multiplier adjusts the temperature. Setting the multiplier to 0 does not disable the nodal applied temperature; it changes the magnitude to 0.

- See the comments under the Application of Loads and Constraints at Duplicate Vertices heading on the Loads and Constraints page for information about how nodal loads are applied at duplicate vertices.