Plate elements are three- or four-node elements formulated in three-dimensional space. These elements are used to model and analyze objects such as pressure vessels, or structures such as automobile body parts.

The out-of-plane rotational DOF is not considered for plate elements. You can apply the other rotational DOFs and all the translational DOFs as needed.

Nodal forces, nodal moments (except when about an axis normal to the element face), pressures (normal to the element face), acceleration/gravity, centrifugal and thermal loads are supported.

Surface-based loads (pressure, surface force, and so on, but not constraints) and element properties (thickness, element normal coordinate, and so on) are applied to an entire plate element. Since these items are based on the surface number of the lines forming the element, and since each element could be composed of lines on four different surface numbers, how these items are applied depend on whether the mesh is created automatically (by either the mesher from a CAD model or the 2D mesh generation), or whether the mesh is created by hand. The surface number of the individual lines that form an element are combined as indicated in Table 1 to create a surface number for the whole element. Loads and properties are then applied to the entire element based on the element's surface number.

|

How Mesh Was Created |

Definition of Surface Number of Element |

|

Midplane Mesh from CAD Model |

All elements coincident with the collapsed surface of the CAD model are on the CAD's surface number regardless of the surface number of the lines. |

|

Plate/Shell Mesh from CAD Model |

All elements coincident with the surface of the CAD model are on the CAD's surface number regardless of the surface number of the lines. |

|

2D Mesh from Sketches |

All elements are assigned to surface number 1 regardless of the surface number of the lines. |

|

Hand-built Mesh and Modified Automatic Meshes |

The highest surface number of any line on the element determines the Surface Number of the entire element. This is the voting rule. |

|

Table 1: Definition of Plate Element Surface Number |

|

When to Use Plate Elements

- The thickness is small with relation to the length and width (approximately 1/10).

- Small displacements and rotations.

- Elements remain planar, no warpage.

- Stress distribution through the thickness is linear.

- No rotation about the direction normal to the element.

Plate Element Parameters

To enter the element parameters, select the Element Definition entry in the tree view for the plate element part or parts, right-click, and choose Edit Element Definition. Alternatively, select the part or parts in the display area or tree view, right-click, and choose Edit Element Data.

Element Data.

Input Included in Element Definition

Material Model: Specify the material model for this part in the Material Model drop-down Menu. If the material properties in all directions are identical, select the Isotropic option. If the material properties vary along two orthogonal axes, select the Orthotropic option. (The orientation of the orthotropic axes is then defined using the Nodal Order Method option. See below.)

Element Formulation: Specify which type of element formulation is used for this part in the Element Formulation drop-down menu. The Veubeke option uses the theory by B. Fraeijs de Veubeke for plate formulation for displaced and equilibrium models. This option is recommended for plate elements that have little or no warpage. The Reduced Shear option uses the constant linear strain triangle (CLST) with reduced shear integration and Hsieh, Clough and Tocher (HCT) plate bending element theories. This option is recommended for plate elements that contain significant warpage. The Linear Strain option uses the CLST without reduced shear integration and HCT plate bending element theories. The Constant Strain option uses the constant strain triangle (CST) and HCT plate bending element theories.

Temperature Method: There are three options for performing a thermal stress analysis with plate elements. These are selected in the Temperature Method drop-down menu. If the Stress Free option is selected, the thermal strain (ε) is calculated as the product of the difference of the nodal temperatures (Tnode) applied to the model and the Stress Free Reference Temperature (Tref), and the thermal coefficient of expansion (α): ε = α(Tnode-Tref). The Stress Free Reference Temperature is entered in the appropriate field of the Element Definition dialog box. If the Mean option is selected, the thermal strain is calculated as the product of the Mean Temperature Difference (entered in the spreadsheet) and the thermal coefficient of expansion: ε = α(Mean Temperature Difference). If the Nodal dT option is selected, the thermal strain is calculated as the product of the difference of the nodal temperatures applied to the model and 0 degrees and the thermal coefficient of expansion: ε = α(Tnode-0). (Also see delta T thru thickness below.)

Twisting coefficient ratio: The undefined rotational degree of freedom (the direction perpendicular to the element) for a plate element is assigned an artificial stiffness to help stabilize the solution. The magnitude of the artificial stiffness equals the Twisting coefficient ratio times the smallest bending stiffness of the element.

The linear plate element is a combination of planar plate and membrane elements. The rotational degree of freedom perpendicular to the plate element is undefined on a local basis. When combined with other plate elements at an angle, the global rotational degree of freedom is defined. (Visualize this as the in-plane rotation in one element having a component in the out-of-plane direction for the adjacent element.) To avoid a singularity (unknown solution) in the solution of the global stiffness matrix, the twisting coefficient is used to create an artificial stiffness on a local basis. This local stiffness is added to the global stiffness matrix. If this artificial stiffness is too large, the solution behaves as if the model is partially tied down in the twisting direction.

Values for the twisting coefficient ratio that are too large may cause a significant artificial constraint, especially where plates meet at an angle. Values that are too small can increase the maximum/minimum stiffness ratio. A large maximum/minimum stiffness ratio may cause a warning and can make the matrix harder to solve, increasing the chance of an inaccurate solution. (The warning is output during the assembly of the stiffness matrix and before the solving operation. It may be followed by solution warnings which are a much more serious indicator of problems.)

The maximum/minimum stiffness ratio is not always independent of the units. If the maximum and minimum stiffnesses were due to tension, then the units of each (such as N/mm) are canceled. With plate elements, the maximum stiffness is often a tension (units of force/length) and the minimum stiffness is often the out-of-plane rotation (units like force*length/radian), so the maximum stiffness divided by the minimum stiffness does have units. The Twisting coefficient ratio may need to be adjusted depending on the units in use.

Properties: The majority of the Element Definition input is entered in a spreadsheet. The specifics of the input depend on the selection in the Properties drop-down menu and the Use mid-plane mesh thickness check box. The options are as follows:

- Properties set to Part-based. all the elements in the part use the same properties regardless of the element's surface number. One row is shown in the spreadsheet.

- Properties set to Surface-based. all the properties in the spreadsheet are entered based on the element's surface number. One row appears in the spreadsheet for each surface number in the part. Some rows may appear because lines exist with the surface number even though no elements have that surface number. The input for such conditions has no effect on the model. (See Table 1 in the previous section What is a Plate Element for the definition of the element's surface number.)

- Use mid-plane mesh thickness is activated. This option is available when the part was created from a CAD model by the automatic midplane mesher. When activated, the thickness of the elements is determined by the midplane mesher, so the Thickness and Design Variable columns are not shown in the spreadsheet.

- Use mid-plane mesh thickness is not activated or disabled. When not activated, you enter the thickness of the elements. The Thickness and Design Variable columns are shown in the spreadsheet. Note: If multiple parts are selected and the Element Definition is modified, the Properties are set to Part-based. If you change it, all the surface numbers that appear in all the selected parts are listed in the spreadsheet. Some surface numbers may not appear in all parts. Be familiar with the model when entering data for multiple parts.

The complete list of columns that appear in the spreadsheet is as follows

- Surface. The surface number of the element. Because of the mesh generation and voting rule (see Table 1 in What is a Plate Element above), some surface numbers may appear in the lines of the mesh but not the surface number of the element. Some surface numbers listed in the spreadsheet (some rows) may have no effect on the part. This column is hidden when the Properties is set to Part-based.

- Design Variable. If the check box is activated, then the thickness of the corresponding elements is a variable for design optimization. This column is hidden when Use mid-plane mesh thickness is activated.

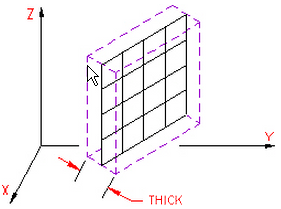

- Thickness. Enter the thickness of the element. The element is considered to be drawn at the midplane of the plate element. Therefore, half of the entered value for thickness is considered on top of the element while the other half is below the midplane. Enter a value for the thickness to run the analysis. This column is hidden when Use mid-plane mesh thickness is activated.

Figure 1: Thickness of a Plate Element

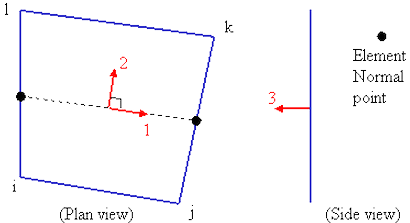

- Normal Point (X), Normal Point (Y), and Normal Point (Z). A point in space is used to control the orientation of the element's normal axis (+3 axis), or which side of the element is the top side (+3 side) and the bottom side (-3 side). The normal direction is determined by specifying a point in space using the Normal Point (X), Normal Point (Y), and Normal Point (Z) columns. See Figure 2. A positive normal pressure is applied normal to the plate elements in the direction of the +3 axis and points away from the element normal point. Tip: The normal point does not need to be over the element as implied by Figure 2. Mathematically, the side of the plate element that faces the element normal coordinate is the bottom of the element.

Figure 2: Determining the Element Normal The edge-on view of the plate element is shown.

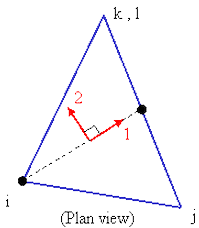

- Nodal Order Method. For a general FEA analysis, you can ignore the element's in-plane orientation (axis 1 and 2). The ability to orient elements is useful for elements with orthotropic material models and for easily interpreting stresses in local element coordinate systems. Which method is used to control the in-plane orientation is done with the Nodal Order Method drop-down menu. If the Default option is selected, the edge of an element with the highest surface number is chosen as the ij side. If the Orient I Node option is selected, the node on an element that is closest to the Nodal Point (see next item) is designated as the i node. The j node is the next node on the element following the right-hand rule about the element's normal axis (+3 axis). If the Orient IJ Side option is selected, the side of an element that is closest to the Nodal Point is designated as the ij side. The i and j nodes are assigned so that the j node can be reached by following the right-hand rule about the element's normal axis (+3 axis) along the element from the i node. Once the i and j nodes and axis 3 are defined, the element's local 1 and 2 axes are determined. See Figure 3.

Figure 3: Local 1 and 2 axes for Plate Elements

The dots along the side of the element are at the midpoint of the side.

- Nodal Point (X), Nodal Point (Y), and Nodal Point (Z). If the Nodal Order Method for in-plane orientation is set to Orient I Node or Orient IJ Side, then use these three columns to enter a coordinate to define the element's in-plane orientation (see previous item).

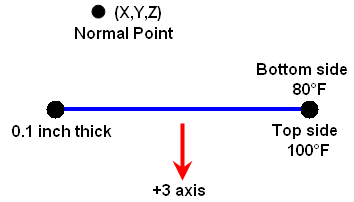

- delta T thru thickness. Regardless of the method selected in the Temperature Method drop-down menu, you can specify the temperature gradient in local 3 direction in the delta T thru thickness column. This is equal to the change in temperature across the plate divided by its thickness: delta T thru thickness = (Ttop-Tbottom)/thickness. See Figure 4. A temperature gradient causes the plate to bend but not to grow or shrink.

Delta T thru thickness = (Ttop - Tbottom) / thickness

= (100 - 80 °F) / (0.1 inch)

= 200 °F/ inch

Figure 4: Temperature Gradient Through a Plate Element

To Use Plate Elements

- Be sure that a unit system is defined.

- Be sure that the model is using a structural analysis type.

- Right-click the Element Type heading for the part that you want to be plate elements.

- Select the Plate command.

- Right-click the Element Definition heading.

- Select the Edit Element Definition command.

- In the Element Definition dialog, select a material model in the Material Model drop-down box. Select Isotropic if the material properties are independent of direction. Select the Orthotropic option if the material properties are dependent of direction.

- If you are performing a thermal stress analysis, select the method that you want to use for calculating the stress in the Temperature Method drop-down box. If the Stress Free option is selected, enter an appropriate value in the Stress Free Reference Temperature field. If the Mean option is selected, enter an appropriate value in the Mean Temperature Difference column.

- If the Use mid-plane mesh thickness is not activated, enter the thickness of the part or each surface.

- If you are going to apply a pressure load or force to these elements, you must define a normal for the elements. You can do this by entering values in the Normal Point (X), Normal Point (Y), and Normal Point (Z) columns of the spreadsheet. A positive pressure load will be defined from this point towards the element.

- Press the OK button.