To get the best mesh possible on a CAD solid model, it is suggested to set the mesh size to the smallest diameter in your model divided by four.

The mesh size should be smaller than the smallest radius of curvature or feature to be modeled. The easiest way to check the mesh size is to look at the edges of small circular holes in the feature file. Each circle should be divided into at least 5 or 6 segments.

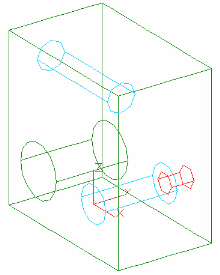

Figure 1 shows the features of a model that was meshed using an appropriate size mesh. Note that the small red hole on the bottom right has its circumference divided into 6 sections.

Figure 1: Features of a Model with an Appropriate Mesh Size

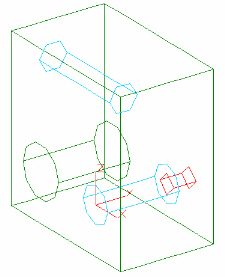

Figure 2 shows the features of a model that was meshed using a mesh size that was too large. Note that the small red hole on the bottom right has its circumference divided into 4 sections.

Figure 2: Features of a Model with a Too Large Mesh Size

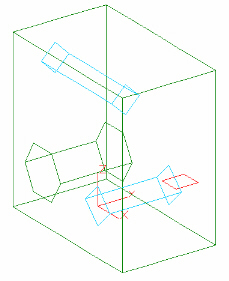

Figure 3 shows the features of a model that was meshed using a mesh size that was much too large. Note that the small red hole on the bottom right has been flattened.

Figure 3: Features of a Model with a Much Too Large Mesh Size