What Do Remote Loads and Constraints Do?

- Adds a nodal load or boundary condition to a point in space; a point not on the model.

- The point in space is connected to selected nodes on the model with line elements.

- You define the properties of the line elements as beam, truss, or similar line elements.

- The remote load or boundary condition is transmitted through the line elements to the model.

- Remote Loads and Constraints differ from Remote Forces, in which the effects of a remote force are applied directly to the model surface using automatically-calculated nodal forces (no line elements are created).

Since the Remote Load & Constraint command generates new geometry and a node at the point in space, you can add any number of additional objects at the new point.

Apply Remote Loads or Constraints

- Use any of the selection commands (Selection

Select) to select where the remote load or constraint is to be distributed onto the model. For example, to apply a torque to the end of a shaft, select the vertices or surface on the end of the shaft. Regardless of what is selected (part, surface, edge, line), the vertices on the selection are used. Most applications require the remote load or constraint to be distributed to three or more vertices not in a straight line.

Select) to select where the remote load or constraint is to be distributed onto the model. For example, to apply a torque to the end of a shaft, select the vertices or surface on the end of the shaft. Regardless of what is selected (part, surface, edge, line), the vertices on the selection are used. Most applications require the remote load or constraint to be distributed to three or more vertices not in a straight line. - Right-click and choose the Add

Remote Loads & Constraints command. This command is also available via the ribbon (Setup

Remote Loads & Constraints command. This command is also available via the ribbon (Setup  Loads

Loads  Remote Load & Constraint).

Remote Load & Constraint). - Use either of the following methods to specify the location of the remote load or constraint.

- Select one vertex or construction vertex and click the Set Load/Constraint Location button. The label under the Set Load Location button indicates 1 vertices.

- If no objects are selected, clicking the Set Load/Constraint Location button prompts you to enter an X, Y, Z location for the remote load. Enter the global coordinate and click the OK button. The label under the Set Load Location button indicates Manual entry.

- The vertices where the remote load or constraint is distributed are already listed by virtue of starting the command with them selected. However, to change the destination or create a new remote load or constraint, select the new location and click the Set Load/Constraint Destination button. The number of vertices in the selection is listed under the button.

- Specify the Part, Surface and Layer attributes for the line elements that connect the remote load to the model. Generally, the part number is a new part number or the same as other remote load elements.

- Click the Generate Elements button. The lines from the remote load to the model are created.

- Click the Add Load/Constraint button to see the list of nodal loads or boundary conditions that can be added. Some of the available options may not be suitable depending on the analysis type and the type of elements used for the load elements.

- If another remote load location is required, repeat the above steps starting with step 3.

- Click the Close button when finished applying all remote loads to all remote locations.

Select

Select  Vertices), right-clicking, and choosing the appropriate entry under the Add command.

Vertices), right-clicking, and choosing the appropriate entry under the Add command. Define Remote Load/Constraint Line Elements

After the remote load or constraint line elements are created, use the browser (tree view) to define the Element Type, Element Definition, and Material. Any line element type can be chosen (beam, truss, gap, and so on), provided it suits the requirements of the analysis. Here are a few guidelines to keep in mind:

- Moments can be applied as a remote load, but they can only be transmitted through beam elements. Truss elements, gap elements, and other line element types that do not have rotational degrees of freedom cannot transmit moments and torques. the joints of these element types are pinned (no translation, rotation allowed). (See Getting Started: Introduction to Autodesk Simulation FEA: Nodes and Elements for additional information on transmitting loads, restraints, and degrees of freedom.)

- Imagine the array of load elements as being supported by boundary conditions instead of connected to the model. The support reactions at these hypothetical boundary conditions are the loads that are transmitted to the model. The total of these support reactions equals the applied loads, but the distribution of the forces and moments may be affected by the stiffness of the load elements.

- Stiff beam elements acts like a rigid structure attached to the model, so the surface (or nodes) of the model where the remote load is distributed tend to keep the same shape but move as a rigid surface. Weak beam elements and truss elements transmits the load but do not completely prevent deformation of the shape of the surface.

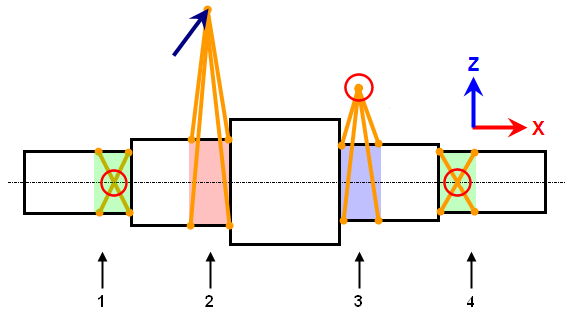

Example – Use of Remote Loads and Remote Constraints

Figures 1 and 2 illustrates how to use remote loads to analyze a shaft (made from brick elements) that is part of a gear train. In the FEA Model, the two boundary conditions at the bearings prevent the shaft from rigid body translations in all directions. The bearing on the left is held radially (Ty and Tz) and axially (Tx, to contain thrust loads), and the mounting of the bearing on the right constrains radial translation (Ty and Tz) but allows axial movement (floating bearing). Assume the bearings are spherical, so that they do not restrain rotation in any direction.

If the load at the pinion were to be modeled with a force, the shaft would still be free to rotate about the axial direction. This would lead to an unstable model and potentially wrong results. A remote boundary condition at the pinion tooth that restrains the model in the tangential direction prevents axial rotation (Rx) and produces the reaction force needed to balance the gear load.

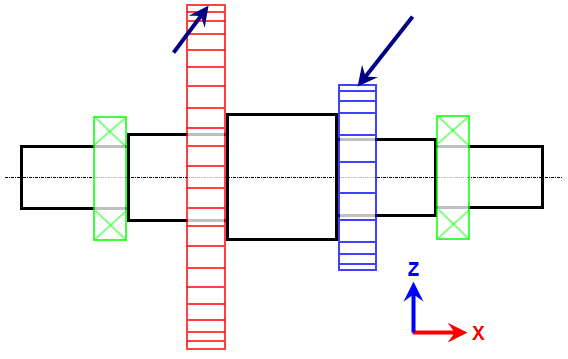

Figure 1: Diagram of Shaft With Gears

|

|

1 - Remote Constraint attached to surface of bearing journal with a no-translation constraint at center of bearing (Tx, Ty, and Tz). 2 - Remote Load attached to gear mounting surface with force applied at gear tooth location. 3 - Remote Constraint attached to pinion mounting surface with boundary condition in tangential direction (Ty). 4 - Remote Constraint attached to surface of bearing journal with axial and radial constraint boundary conditions (Ty and Tz). |

|

Figure 2: Equivalent FEA Model Using Remote Loads |

CAD Additions

CAD Additions  Joint command can be used for the bearings to create universal-type joints. The result is the same geometry as created by the remote load command.

Joint command can be used for the bearings to create universal-type joints. The result is the same geometry as created by the remote load command.