This material model is available for 2D, brick, tetrahedral, membrane, and shell elements. The Ogden material model is a hyperelastic material model that has three material constants. If you press the Curve fit button in the Element Material Specification dialog, you will be able to input experimental stress-strain data and the three material constants will be calculated from the experimental stress-strain data. The software supports up to a sixth-order Ogden material. The Ogden material properties are listed below. In addition to these properties, it may be necessary to define some Isotropic Material Properties.

Click the Curve Fit button on the Element Material Specification dialog to use the Curve Fitting routine. This routine calculates the material constants using measured stress-strain data.

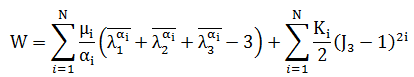

The potential function of the Ogden material is as follows:

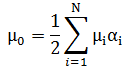

If N=2, α1=2, and α2=-2, the Mooney-Rivlin material model is obtained. If N=1 and α1=2, Ogden's model degenerates to the Neo-Hookean material model. In the Ogden form the initial shear modulus, µ0, depends on all coefficients:

where μiαi > 0, i = 1,..,N

The initial bulk modulus follows from:

k0 = K1

References:

[1] R.W.Ogden et al, Fitting hyperelastic models to experimental data, Computational Mechanics 34 (2004) 484-502.

[2] L.R.G. Treloar, Stress-strain data for vulcanized rubber under various types of deformation, Trans. Faraday Soc. (40) 59-70.

Material Properties:

- Mu: This is the first Ogden material model constant (μi). This must be defined for each order of the Ogden material model being used.

- Alpha: This is the second Ogden material model constant (αi). This must be defined for each order of the Ogden material model being used.

- KB: This is the third Ogden material model constant (Ki) which represents the bulk modulus. This must be defined for each order of the Ogden material model being used.

- Order of Bulk Modulus: This is equal to the number of rows (N) in the data table. This cannot exceed 6.