Compare the predictions of failure initiation for a linear elastic analysis.

In Abaqus Standard, five failure criteria are provided for use in linear elastic analyses: four stress-based criteria and one strain-based criterion. The practical utility of these linear elastic failure criteria is quite limited because they only predict the occurrence of localized failure, not the consequences of localized failure. In other words, when one of the Abaqus failure criteria predicts that failure occurs, there is no accompanying stiffness reduction. Therefore, the processes of load re-distribution and progressive failure are not represented. In contrast, Simulation Composite Analysis not only predicts localized failure, it also predicts localized stiffness reduction. In further contrast, the Abaqus linear elastic failure criterion utilizes the homogenized composite state of stress or strain to predict failure of the homogenized composite material, whereas Simulation Composite Analysis utilizes constituent average stress to independently predict failure of each constituent material.

In this example problem, the composite conic can be assumed to be linearly elastic prior to global failure. In that respect, failure initiation predicted by Simulation Composite Analysis can be compared with the failure initiation predicted by the different Abaqus failure criteria. The failure criteria provided by Abaqus are applicable to generally orthotropic materials, but for the purpose of this example problem, a transversely isotropic material model is used for both the Abaqus failure criteria and Simulation Composite Analysis. One of the shortcomings of the Abaqus linear elastic failure criteria is that they are based entirely upon an assumed condition of plane stress. Consequently, they can only be used in plane stress 2-D continuum elements or shell elements. While Simulation Composite Analysis uses a general 3-D state of stress in its applicable failure criteria, continuum shell elements (SC8R) are used in the comparison in order to accommodate the limitations of the Abaqus linear elastic failure criteria.

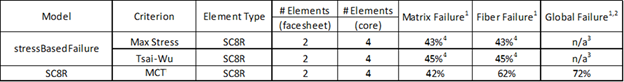

In the case of composite laminates, laminate failure is taken to be first ply failure. For brevity, only the Abaqus max-stress and Tsai-Wu failure criteria (stress-based failure criteria) are compared with the Simulation Composite Analysis MCT failure criteria. For more information on the max-stress and Tsai-Wu failure criteria formulation, see section 18.2.3 of the Abaqus Analysis User's Manual.

Models

ASCA_EP1_SC8R.inp

- Failure criteria: MCT

- Element type: SC8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

ASCA_EP1_stressBasedFailure.inp

- Failure criteria:

- Max-Stress and

- Tsai-Wu

- Element type: SC8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

Results

- Load percentage is on a 0-100% scale

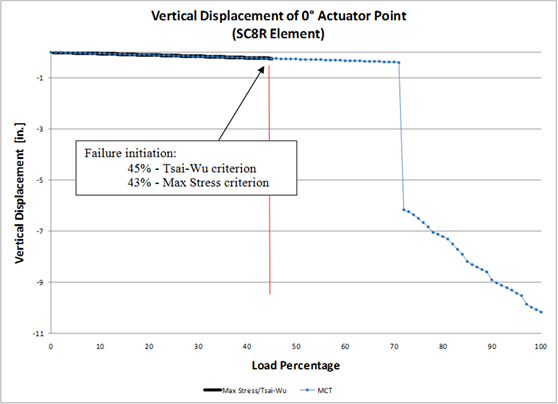

- Global failure is defined as a large discontinuity in the load-vertical displacement curve for the 0° application point of the load head shown previously

- Global failure is unable to be determined, see text for details

- Composite laminate failure

The plot below displays the load-displacement curves for the load application point at 0°. Before global failure is achieved (72%), both methods produce similar predictions for overall structural stiffness. In using the linear elastic material failure criteria available in Abaqus, material stiffness degradation is not accounted for. Therefore, the failure analysis can only proceed up to the point where localized failure initiation is predicted. The capability of Simulation Composite Analysis to degrade material stiffness at integration points that have failed (either matrix of fiber failure) lends the unique capability of accurately capturing the progression of local failure initiation into eventual global failure. An important concept to note is that the composite structure retains most of its structural stiffness well past the initiation of local failure. Designs where failure is predicted using first-ply failure are often grossly conservative and the full capabilities of the composite structure will not be recognized. Along with this, you can accurately describe the post-fail behavior of the structure with Simulation Composite Analysis, something that is not available with the Abaqus failure criteria.