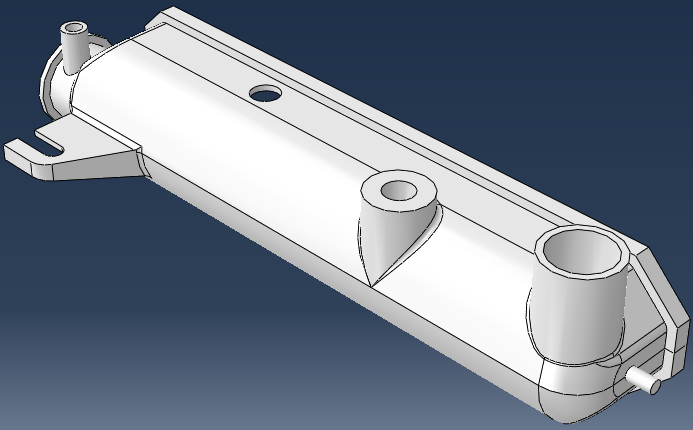

The following tutorial provides step-by-step instructions to analyze a fiber-filled part using Moldflow, Advanced Material Exchange, and Abaqus. The radiator tank part is made with Ultramid 8223G HS glass fiber-reinforced material.

The radiator tank model is imported into Moldflow so that a Fill + Pack analysis can be run to determine the orientations of the fiber-filled part. The model is opened with Abaqus/CAE, where loads and boundary conditions can be applied to the model.

Once models are created in Moldflow and Abaqus, we will use Advanced Material Exchange to map the fiber orientations onto the structural model. At this point, we export the results of the mapping sequence for use in a structural analysis with Abaqus.