Examine the results of the composite tube problem.

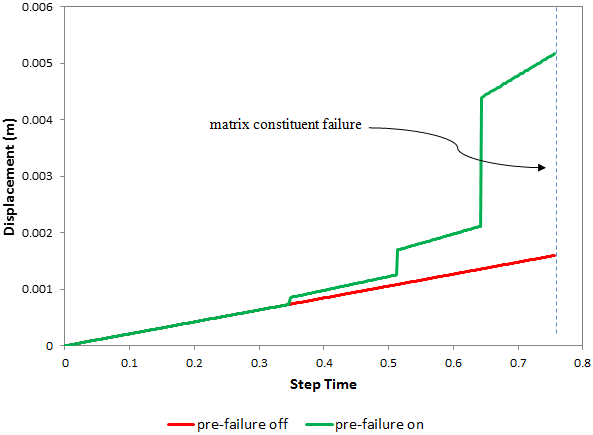

The plot below shows the displacement of the nodes located on the outer radius of the top surface of the tube for cases when pre-failure is turned off and when it is turned on. The displacement of the model run without pre-failure is linear up to a displacement of 0.0016 m, at which point matrix constituent failure occurs throughout the model. With pre-failure on, the displacement is linear up to a displacement of 0.00072 m, then diverges from the pre-failure off results as a consequence of the three discrete reductions in shear stiffness that occur prior to matrix failure. Note the significant difference in displacements at failure between the two curves. With pre-fail off the displacement is 0.0016 m and with pre-fail on the displacement is 0.0051 m.

The following input files were used to generate the results discussed here and can be found in the "doc" folder in the Simulation Composite Analysis installation directory:

- ASCA_EP2_SingleElement_PreFail_Off.ans

- ASCA_EP2_SingleElement_PreFail_On.ans

- ASCA_EP2_Tube_PreFail_Off.ans

- ASCA_EP2_Tube_PreFail_On.ans

Before running these jobs, ensure that the material reference number (matID) value in the .ans files matches the matID value for SilEglass1200tex-MY750 in the ASCAMatDB.xml file that resides in the Simulation Composite Analysis Material Directory.