Define the linear elastic material for the ply section.

Simulation Composite Analysis cohesive materials can be used in the same model with standard (ply based) Simulation Composite Analysis materials. In fact, the ability of the tool to robustly determine solutions for analyses that have both intralaminar (fiber and matrix damage) and interlaminar (delamination) is one of its main advantages. Since the focus of this tutorial is the demonstration of the cohesive functionality of Simulation Composite Analysis, the ply material response will be linear elastic (i.e. failure is not permitted to occur in the plies). Refer to Tutorial 1 for a demonstration of the ply-based failure capabilities.

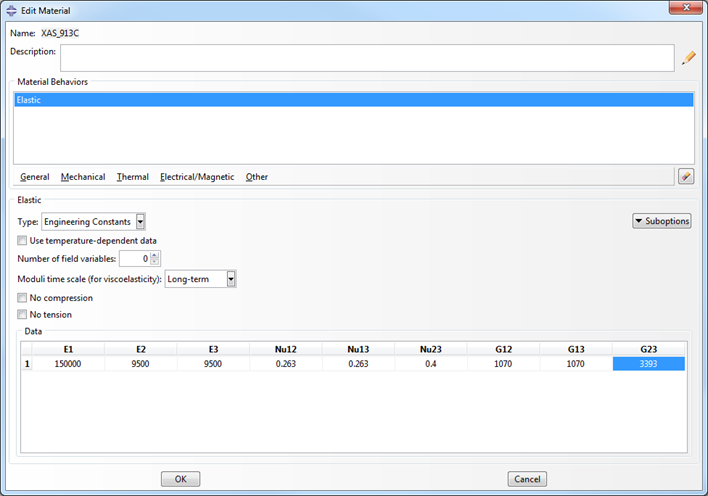

The material properties [1] for the linear elastic ply material are given below. This material is used to define the ply section, not the cohesive section.

E11 = 150 GPa

E22 = E33 = 9.5 GPa

v12 = v13 = 0.263

v23 (assumed) = 0.4

G12 = G13 = 1.07 GPa

G23 (assumed) = 3.393 GPa

- Using the Property module, create a new material () that is Elastic and of type Engineering Constants and enter the values from above in units of N-mm. Name the material XAS_913C. The completed Edit Material dialog box should appear as shown below.