The progressive fatigue feature predicts the cycles to failure of a given composite material under a prescribed load history. Within Simulation Composite Analysis, it is used to aid in progressive fatigue analyses. This is accomplished by damaging the composite material with the minimum cycles to failure and allowing the finite element platform to redistribute loading to the adjacent material. Following this fashion, a composite structure can be analyzed within a finite element platform, and the cycles to failure for the structure can be estimated.

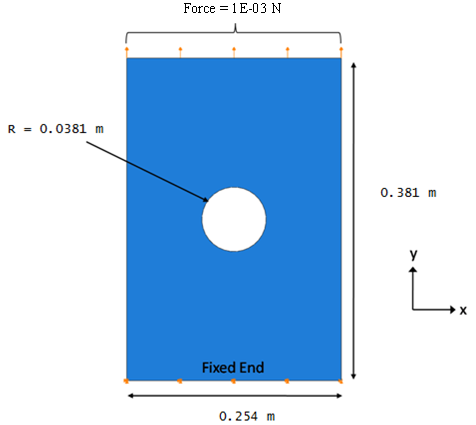

The problem consists of a flat composite plate with a hole in the center subject to fixed boundary conditions on one end, and a maximum load of 0.001 (N) on the other end. The plate is made of a unidirectional material. The layup is [0/±45/90]s, and the ply thickness is 0.000127 m which results in a plate thickness of 0.001016 m. The load ratio Smin/Smax is 0.1 and the frequency of loading is 10 Hz. The seed size for the mesh is 0.006 and eight noded isoparametric brick elements with reduced integration are used. The dimensions, boundary conditions, and load are shown below.

In this tutorial, elementary modeling details are omitted. It is assumed you have previous experience in the Abaqus/CAE environment. Please refer to the Abaqus documentation before completing this tutorial if you are unfamiliar with Abaqus/CAE.

A completed input file (ASCA_Tutorial_5_Abaqus.inp) for this tutorial is available for download here.