The Create Composite Material plug-in within Abaqus/CAE lets you choose a variety of material and analysis options.

The material and analysis options include:

- Selection of a composite material to use in the analysis (Simulation Composite Analysis-compatible material characterizations must be created outside of Abaqus/CAE using Composite Material Manager)

- The choice of four unit systems

- Selection of the principle material direction

- Calculation method for failed plain weave properties

- Inclusion of hydrostatic pressure induced material strength enhancement

- Stiffness degradation method (instantaneous, energy based or none)

- Inclusion of pre-failure nonlinearity

- Setting the matrix and fiber constituent stiffness post-failure degradation ratios (traditional degradation) or degradation energies (energy based degradation)

- Creating additional output variables that provide fiber and matrix constituent stresses and strains

Using these options, you can tailor a specific analysis to the requirements of the problem. For a detailed discussion of the options available, refer to the Simulation Composite Analysis User's Guide.

Note: There are two Simulation Composite Analysis plug-ins. The Create Composite Material plug-in is used for ply based materials and the Create Cohesive Material plug-in is used to define cohesive materials.

Create the Material

In the following steps, a user-material is created for the plate, and progressive failure analysis is requested using the Create Composite Material plug-in.

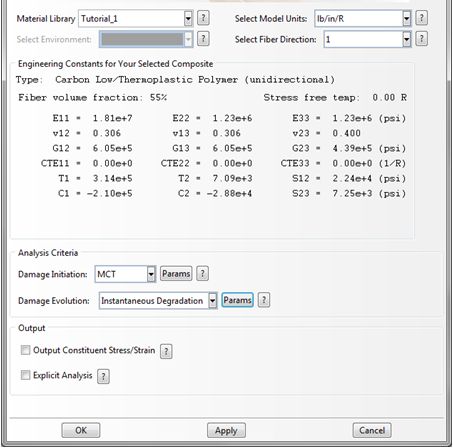

- Select from the main toolbar. The Create Composite Material plug-in appears.

- From the Material Library list, select the material you created in the previous section, Tutorial_1.

Note: The unit system dependent Engineering Constants specific to this material are listed in the dialog box for you to review.

- Select lb/in/R from the Select Model Units list.

- There are 4 unit systems to choose from. The default unit system is N/m/K.

- Select 1 as the fiber direction.

- 2 can also be used as the fiber direction, but it would require a different composite layup orientation than the 1 direction. As a general rule, it is recommended that 1 be used as the fiber direction to maintain consistency from model to model. On occasion, however, it will not be possible to create an orientation in Abaqus that allows for the 1 direction to be the fiber direction due to the combination of complex model geometry and section orientation limitations. In such cases, it may be necessary to use the 2 direction as the fiber direction.

- Accept the remaining default settings for the Analysis Criteria and Output options.

- The dialog box should appear as shown below.

- Click OK.

After completing these steps, a user material is created. This material is used to define the composite layup for the plate.