Predict the progressive failure response of the composite structure using three finite element models.

The models only differ in the type of element, i.e., the materials, mesh density, and boundary conditions are exactly the same in each model. Three Abaqus element types are tested: C3D8R, C3D8 and SC8R. Each of the three models uses the same through-the-thickness mesh density. Four elements were used for the foam core and each composite facesheet is divided into two elements for a total of eight elements through the thickness of the sandwich laminate.

Models

ASCA_EP1_C3D8.inp

- Element type: C3D8

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

ASCA_EP1_SC8R.inp

- Element type: SC8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

Results

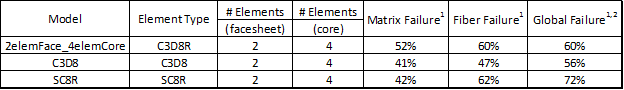

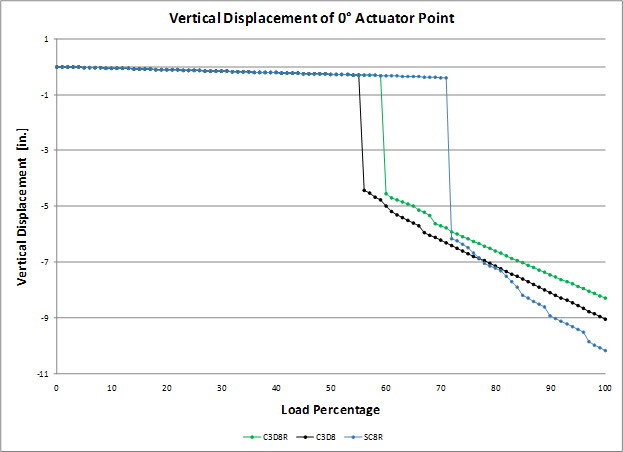

The table below displays the load level at which each type of failure event is predicted by the three models. The figure below displays the overall vertical load-displacement curves for the composite structure predicted by the three models.

- Load percentage is on a 0-100% scale

- Global failure is defined as a large discontinuity in the load-vertical displacement curve for the 0° application point of the load head shown previously

Comparing reduced integration continuum elements with fully integrated continuum elements (C3D8R vs. C3D8), the following observations and explanations are given:

- A fully integrated element type results in local failure events (matrix and fiber failure) occurring at lower load levels.

The fully integrated element utilizes more Gaussian integration points than the reduced integration element. Even if both elements predict the same element average stresses, the fully integrated element will predict a higher local peak stress than the reduced integration element simply because it has more Gaussian integration points and it contains Gauss points that are closer to the element's boundaries (where the linear stress distribution attains a maxima). Consequently, the fully integrated element will predict localized failure initiation at a lower load level than the reduced integration element.

- Global failure occurs at a lower load level with the fully integrated continuum element.

The difference in the global failure load predicted by the two elements is due primarily to differences in the local failure initiation load. The reduced integration element, with a single Gauss point per material ply, provides a more discretized representation of failure cascading. In other words, when failure occurs in a material ply of a reduced integration element, the stiffness of the entire ply is reduced and a relatively large amount of load re-distribution occurs. In contrast, when failure occurs at one of the Gauss points in a material ply of a fully integrated element, only part of the material ply experiences a stiffness reduction and a relatively small amount of load re-distribution occurs.

You might be tempted to think that a fully integrated element inherently provides a more realistic progressive failure response since it contains numerous integration points where the failure criteria is tested and stiffness reduction is imposed. This is not true because the integration points of a fully integrated element are not the most accurate locations for computing stress. In fact, the most accurate locations for computing stress are the reduced integration points [1]. Consequently, the reduced integration elements evaluate failure and stiffness reduction at fewer points, but the evaluation itself is more accurate because the stress state is more accurate at the reduced integration points. Therefore, the use of more integration points per element does not necessarily result in a more accurate analysis.

In comparing the failure response of the reduced integration continuum elements (C3D8R) with reduced integration continuum shell elements (SC8R), the following observations and explanations are given:

- The continuum shell elements predict local failure initiation at lower load levels (42%) than the reduced integration continuum elements (52%).

Even though both elements make use of the exact same set of Gaussian integration points, the SC8R elements predict higher in-plane stress components than the C3D8R elements. This discrepancy is due to differences in the transverse shear and transverse normal stiffnesses of the two elements. The C3D8R element obtains its transverse stiffnesses by simply integrating the stiffness of the individual material plies over the volume of the element. However, the SC8R element obtains its transverse stiffnesses as direct user input that applies to the element as a whole. This scenario effectively precludes the possibility of both elements exhibiting the same transverse stiffness. Any change in the transverse stiffness of an element will necessarily result in a different division of the element's total strain energy into in-plane and out-of-plane components. Therefore, if the two elements have different transverse stiffnesses, they will likely have different in-plane stress components. In this particular problem, the initial matrix failure is primarily driven by the in-plane shear stress which is higher in the SC8R element than in the C3D8R element; consequently, the SC8R element predicts earlier localized matrix failure.

- Global failure occurs at a higher load level with the continuum shell element even though local failures occur at much lower load levels.

Even though the SC8R element predicts initiation of localized constituent failure at a lower load level than the C3D8R element, the SC8R element predicts that global structural failure occurs at a higher load level (72%) than the C3D8R element (60%). The fact that the SC8R predicts a more gradual failure cascade process is due primarily to the fact that localized material failures do not affect the transverse stiffnesses (E33, G13, G23) in the SC8R element (Abaqus requires these stiffnesses to be constant in the SC8R element). Since the transverse stiffnesses do not experience any degradation, the SC8R elements can more easily accommodate load re-distribution without causing additional localized failures. To summarize, the C3D8R and SC8R elements exhibit very different failure cascade behavior.