A unique material characterization must be performed for each material used with Simulation Composite Analysis.

A stand-alone graphical-user-interface program called Composite Material Manager is installed with Simulation Composite Analysis. It is used to characterize composite materials for use with the software. The steps to create a new composite material with Composite Material Manager are described in this section.

The properties [2] for the material used in this Tutorial, T700/2510, are given in the table below. We will be comparing OHT data at 75 °F so it is appropriate to use the RTD properties. Further, since the plate is loaded in tension, it is appropriate to use the tensile moduli for the characterization of the material.

It is common for datasheets to be missing a few properties required by Simulation Composite Analysis. In this case, our source of data is missing the intralaminar stiffness (ν23 or G23) and intralaminar strength (S23). S23 is not required but should be included in analyses where significant intralaminar stresses are present. When properties are missing they should be estimated based on similar materials and engineering judgment. Common values [3,4] for ν23 and S23 for carbon/epoxy unidirectional materials are 0.4 and 7.25 ksi.

Since the MCT failure criterion in Simulation Composite Analysis decomposes the lamina-level stresses into fiber and matrix stresses, the fiber and matrix stiffnesses must also be provided. Accurate fiber and matrix properties are not as important as accurate lamina properties because they are iteratively tuned to match the specified lamina properties and volume fraction. Ideally, properties for the fiber and matrix would be known and entered. However, it is most often the case that the properties are not known and default properties should be entered. Composite Material Manager comes pre-populated with default fiber and matrix values for carbon/epoxy, glass/epoxy, and Kevlar/epoxy materials.

Characterize the Material

- Open the Composite Material Manager GUI and select .

- Enter the material name as Tutorial_1.

- Select lb/in/R as the unit system, Carbon Low as the Fiber Type, Thermoset Polymer as the Matrix Type, and enter the fiber volume fraction, 0.55.

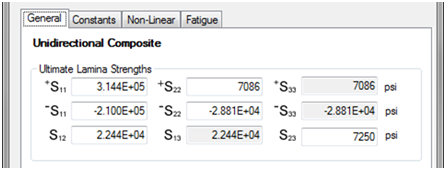

- Fill out the General tab by entering the RTD lamina strengths given in the table above. It is not necessary to enter the compressive strengths with a "-" sign. The GUI should appear as shown below.

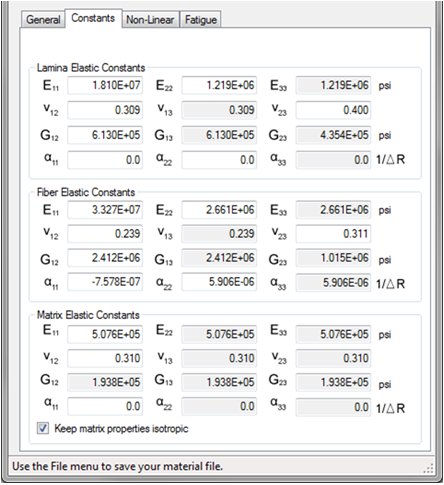

- Fill out the Constants tab with the RTD tensile lamina stiffnesses given in the table. Click the Apply Material Type Characteristics button to apply the fiber and matrix stiffnesses. The GUI should appear as shown below.

- Select , then select OK when prompted to optimize the material. Save the material in the default directory.

- After the material is saved, the converged properties are displayed in Composite Material Manager.