In situations where volume computation should not occur, you can define gaps in the materials.

A gap can be used where there is one gap in the material, such as a bridge location. Gaps can also be used in multiple locations, where there are non-contiguous pockets of a material along the length of a corridor.

Gaps are defined in the Sample Line Group Properties, Material List tab.

Run In and Run Out Distances For Gaps

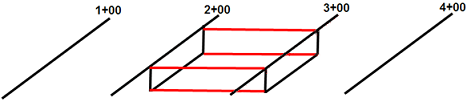

Gaps can have run in and run out distances which act as transition areas between materials. By default the gaps have run in and run out values of zero. No material is interpolated beyond the gap stations, as shown in the following illustration.

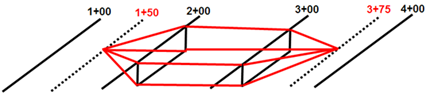

If marsh material is present between station 2+00 and 3+00 with short transitions before and after, you can specify run in and run out instead of adding more sample lines, as shown in the following illustration.

The run in for the material is defined in the first gap, and the run out for the material is defined in the second gap. Therefore, the first gap would have a run in of 50, and the second gap would have a run out of 75.

If you want to have tighter control on the run ins and run outs, you can set smaller values or keep the default of zero.

Defining Gaps for Pockets of Material

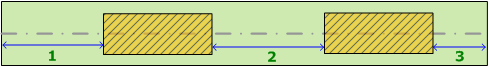

In the following example, three materials are defined: Cut, Fill, and Marsh material. The Marsh material exists only at the hatched areas in the illustration. All three materials must be added into one material list because the cumulative cut/fill calculations should include all three types.

For this example, you would add 3 gaps (as represented by numbers 1, 2, and 3 in the illustration) with appropriate run ins and run outs for material transitions. In the material list the gaps should only be applied to Marsh material and not for the materials named Cut and Fill.