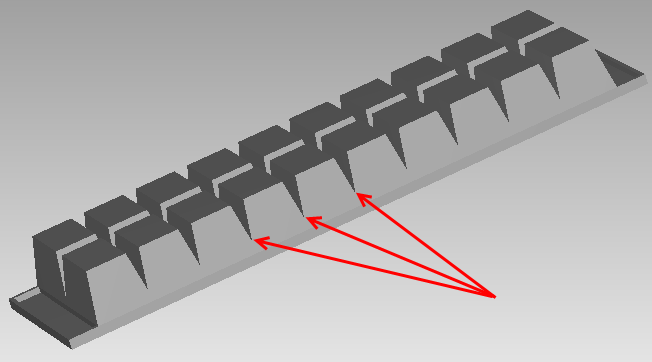

Thin gaps in a finished part may need to molded using a thin metal protrusion in the mold. A thin metal section is called a knife edge.

Knife edges have a tendency to break, causing the mold to fail prematurely.

This is especially true if the knife edge section of the mold is formed out of one of the softer mold materials such as copper, copper/beryllium alloy or aluminium. Ensure that the Configuration settings values used to assess the acceptable mold thickness are appropriate for the material being used.

Where possible, the design should avoid knife edges.

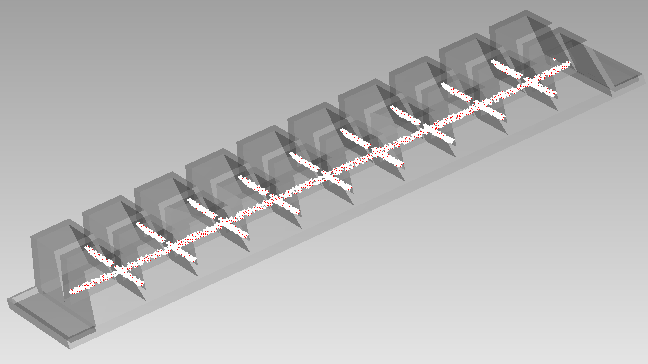

To view the knife edge contribution to the indicator value, click . Click on Knife edge and any problem areas will be highlighted on the part.

Tip: For large, complex models that do not have knife edge issues, turning off the knife edge option in the Rule Configuration dialog () could increase performance.