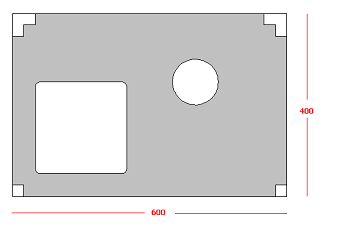

Often the user is given fixed size sheared blanks by the customer that only requires internal holes and notches cutting out. Example : 600 x 400 SS-306 blank with notches and holes.

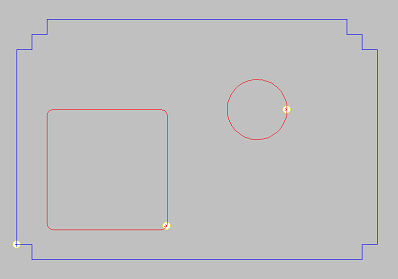

- First accurately draw the part as required using Opus, and check it looks correct in Profiler.

- Alternatively import the part as a DXF file.

- Save the part in a folder.

Next we are going to assign a Null Tool to the elements that do not require cutting and then write the NC from Profiler. Note that there is no requirement to place the part in a job or to nest from a job.

- From the Profile menu Click on Tools.

- Click on each of the 4 main lines of the outside of the part.

- These 4 will be hi-lighted (dotted yellow).

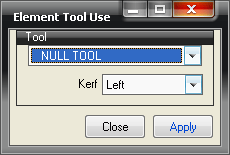

- When all are selected, Right-Click and the Tool Use menu will be displayed.

- Change the tool to be Null Tool.

- Apply and Close.

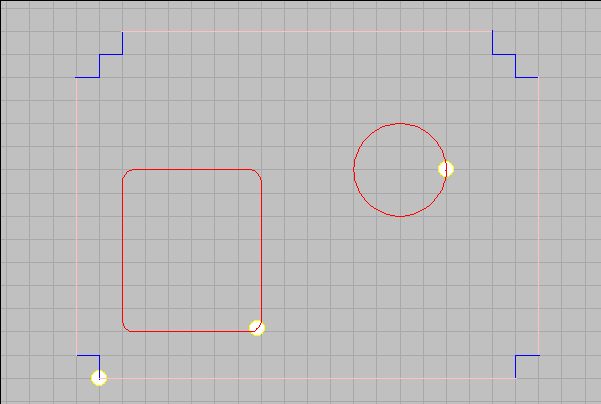

The 4 lines will now be in pink, showing that these have been assigned the Null Tool. These lines will not be cut but are used as references for the tool movements.

Note: The lead-in's and lead-outs are outside of the part. (the default lead-in's are 4mm).

- After mounting the plate you may require to place some scrap up to the blank where the lead-in's start.

- You could delete the lead-ins, however the torch may not start on the very edge of the part.

- Also the start usually gives an initial bad cut, that is why lead-in's are used.

- From the Profile menu Click on Write NC.

- Enter a number for the job.

- This can then be downloaded at any time from your Plasma Controller.

- From the Utilities menu select View NC.

- S elect the NC Number saved in previous step.

- Click on the green arrows to examine the cuts that will be made.

- Note: Place the left bottom corner of the blank plate exactly under the torch. This could be anywhere on the bed of the cutter.

- Make sure the blank is parallel to the bed.

- Mount some scrap around the lead-ins.